In the wake of the tragic Mumbai hoarding collapse in May 2024, which resulted in 14 fatalities and numerous injuries, the importance of robust structural analysis has never been more apparent. At the forefront of this are Finite Element Analysis, or FEA, and wind load analysis.

FEA breaks down complex structures into smaller, manageable elements. This allows engineers to simulate how structures respond to various forces, including wind loads. Wind load analysis, on the other hand, focuses specifically on how wind interacts with structures, considering factors such as wind speed, direction, and turbulence.

FEA and wind load analysis work together to predict and prevent structural failures. By simulating wind forces on a structure, engineers can find weak points, analyze stress, and create safer designs. This is especially important as buildings become taller and more complex. These tools are crucial for preventing disasters and pushing the boundaries of structural engineering.

This article delves into the intricacies of FEA and Wind Load Analysis, exploring their applications. We’ll also examine how these methods when combined with Computational Fluid Dynamics (CFD) for fire and smoke modeling, create a powerful trifecta for comprehensive structural safety analysis.

Here, we’ll talk about how FEA and wind load analysis could support structural analysis when paired with CFD fire and smoke modeling. However, if we look back, we can ponder upon the technical evidence that showed some red flags.

Structural Analysis: A structural analysis of the hoarding conducted by Veermata Jijabai Technological Institute (VJTI) implied that the structure did not meet the necessary safety standards. It also highlighted technical issues, including:

Insufficient Foundation: The foundation of the structure collapsed due to alarming wind loads since it was not strong enough.

Inadequate Structural Design: While designing, it was believed that the engineers needed to take into account the wind loads that may have led to the disaster.

Wind Speed and Direction: The presence of a wind speed of 96 kmph at Ghatkopar during the collapse, as reported by Indian Meteorological Department (IMD). This was higher than the average wind speed in the area.

Now that we are aware of the specifics, the following are the scenarios in which FEA and wind load analysis along with CFD fire and smoke modeling could be used:

Turbulence Modeling: CFD fire and smoke modeling uses turbulence models like k-epsilon or Large Eddy Simulation (LES) that are found to predict the movements of fire and smoke in an open environment or within confined spaces.

Boundary Conditions: Boundary conditions, including temperature and heat flux, are defined using FEA. This encapsulates the building components’ structural and thermal behavior.

Thermal Properties: The thermal characteristics of building materials, such as their thermal diffusivity, specific heat capacity, and thermal conductivity, are also provided by FEA. Conduction, convection, and radiation of heat within the structure are all modeled using these properties.

Smoke Management: Simulating smoke movement and concentration levels using CFD fire and smoke modeling and FEA allows for the design of smoke management systems. This is to protect structures from smoke-related damage and to preserve visibility during the evacuation.

Identify Potential Failure Points: Engineers can reinforce a structure’s weak spots and avert catastrophic breakdowns by using FEA to locate those places.

Multi-Physics Simulation: The simulation of both structural reactions to mechanical loads (such as wind) is made possible by the combination of FEA and CFD fire and smoke modeling. This method provides a thorough knowledge of how these loads interact and impact the overall stability of structures like hoardings.

Structural Analysis with FEA: FEA and wind load analysis can be used to model the structural response of hoardings to wind loads by breaking down the structure into finite elements and applying boundary conditions and material properties. It calculates the stress distribution, deformation, and points of failure under varying wind speeds and directions.

We at Mechartes take great pride in leading the way in wind load analysis and FEA for large structures. Having been in the business for more than 15 years, we have made a name for ourselves as leading experts in this area.

When it comes to examining the structural integrity of substantial structures, bridges, and other infrastructure, FEA is a potent option in our toolbox.

But our expertise continues beyond there. We also specialize in CFD fire and smoke modeling, which is important in ensuring the safety and resilience of large structures.

At Mechartes, we believe that the integration of FEA and wind load analysis along with CFD fire and smoke modeling, is the key to unlocking the full potential of large structure design and safety.

By combining these powerful tools, we can provide our clients with a comprehensive understanding of how their structures will perform under a wide range of loading conditions, including the critical factor of wind.

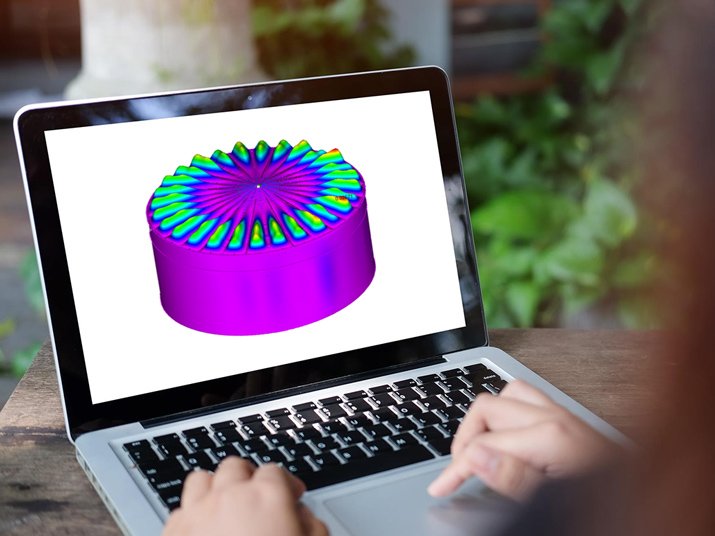

We conducted a case study to show FEA and CFD Fire Simulation Chamber Analysis. Here are the details:

The goal was to analyze peak stresses on the main force-resisting members of the Chamber under wind and thermal loads using FEM. This involved assessing stresses and loads on connections like constraints and welds, comparing them visually and through hand calculations against allowable limits of materials and fasteners.

The methodology included the following:

The Fire Simulation Chamber included a 2 m wide platform at a height of 2.5 m along three sides of the chamber. This platform was constructed from a suitable stainless steel grade (SS-304) with a thickness of 6 mm and an inclined support arrangement to withstand a total load of 50 kg/ft².

The study involved weld calculations for structural members based on the maximum forces obtained from the FEA.

The analysis considered various possible loads, including static weight, wind loads, and thermal loads, both individually and in combination.

The support structure, comprising various C Section beams and Box channel beams, was modeled using 1D beam elements. The platform itself was modeled using 2D Shell Elements, on which a uniformly distributed load (UDL) of 50 kg/ft² was applied.

The analysis led to several key recommendations and modifications to enhance the structural integrity of the Fire Simulation Chamber:

Strengthening the Platform: Additional channels were added to strengthen the platform.

Weld Enhancements: C-Channels were reinforced with additional 3″ x3″ gusset plates to improve weld strength.

Anchoring Solutions: Expansion bolts of minimum size, along with their specific locations and plate sizes, were suggested.

Concrete Specifications: Concrete of grade 43N/mm² was recommended for use.

For more information click here.

Understanding FEA and wind load analysis is crucial for ensuring the structural safety of large buildings and infrastructure. Mechartes specializes in employing FEA and wind load analysis to predict and mitigate potential risks.

By integrating these advanced analytical tools, we provide comprehensive insights into structural behavior under varying conditions, enabling optimized design and enhanced safety measures.

For further inquiries or to explore our services in FEA and wind load analysis as well as CFD modeling, please contact us today!