Pulsation analysis of reciprocating pumps is the method of analyzing the pulsation effects, such as pressure and flow fluctuations of fluid, that occur during their operations due to the working principle of reciprocating pumps.

Pulsation severely impacts the performance of the pump and piping systems and causes decreased overall efficiency of the system. Therefore, it’s crucial to conduct a pulsation analysis of reciprocating pumps to evaluate and optimize the pumping system to mitigate the effects of pulsation.

So, this article will guide you through the pulsation analysis of positive displacement pumps. Still, it’s essential to understand what pulsation is and its effect on pumps and piping systems.

What is Pulsation in Positive Displacement Pumps?

Pulsation occurs in reciprocating pumps, also known as positive displacement pumps. In this type of pump, the fluid is transferred by repeated back-and-forth motion of the piston or diaphragm, which causes fluid pressure and flow rate fluctuation, also known as pulsation.

This fluctuation can significantly impact the performance and lifespan of the pump and the piping system it is connected to by causing excessive vibration, noise, and stress on the pump and its components and, in turn, wear and tear on the pump.

Effects of Pulsation

-

Damages Critical Components of the Pumping System

Increased vibration and stress caused by pulsation can also lead to the pump’s bearing, seals, and other components breaking down more quickly, which will require repair and downtime.

-

Adverse Effects on Piping Systems

The pulsation can also cause problems for piping systems. High pulsation can result in the pump’s expansion and contraction, leading to leaks and other issues.

-

Increases Operational Costs

Overall, pulsation causes significant issues, reducing efficiency, increasing maintenance costs, etc.

These impacts make it imperative to do a pulsation study of the reciprocating system so that it can be designed to produce a minimum pulsation effect when operating.

Design Approaches in Pulsation Analysis of Positive Displacement Pumps

According to American Petroleum Institute (API 164), there are two design approaches, namely design approach 1 and design approach 2, depending on the application of the reciprocating pumps. Each design approach involves a different analysis.

For example, design approach 1 is applied to basic pumping units. No pulsation study is required in this approach, and a proper engineering inspection is enough.

Design approach 2 applies to medium-risk units with these specifications: critical applications operating above 200 RPM or multiple units are online, or high power- above 50k. It involves pulsation analysis and a basic mechanical review of the piping system.

5 Pulsation Conditions That Can Be Assessed via Pulsation Analysis

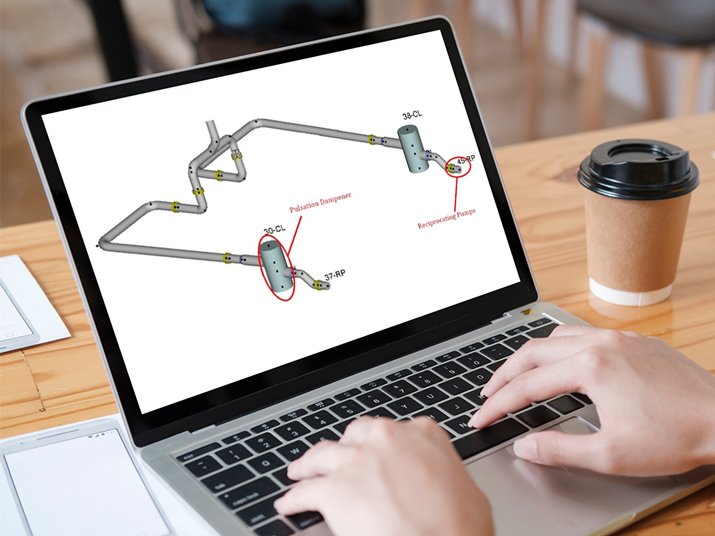

Pulsation analysis is carried out in computer simulation software to evaluate different pulsation conditions such as:

1. Pressure Pulsation

Pressure pulsation is the oscillation in pressure of fluid flow in the reciprocating pump due to the reciprocating action of the piston of the pump. It has the most significant impact on the pump and its piping system, such as it causes excessive piping vibration, shocks, cavitations, failure of valves, etc.

So, it is crucial to study the magnitude of pressure pulsation to organize the systems and have pressure pulsation under the acceptable limit.

2. Pressure Drop

Pressure drop is the immediate fall of pressure that occurs in the pump because of the fluid supply cut-off during the piston’s stroke of the pump. This condition can have a considerable impact on the performance of the pump and piping system as it affects the flow rate, energy consumption, and overall efficiency of the system.

High-pressure drops can lead to increased costs and reduced performance. Therefore, it is imperative to measure and analyze the pressure drop in pulsation analysis and optimize the system.

3. Pulsation Level

The pulsation level is the pump’s highest and lowest fluid pressure variation in pulsation analysis. It is measured pressure in units, such as pounds per square( psi) or pascal (pa). It can vary depending on many factors, such as the properties of the fluid, the flow rate of the fluid, and the design of the piping system. The higher the pulsation level, the more negative impact it has on the pump and piping systems.

Therefore, it’s crucial to analyze the pulsation level in the pulsation analysis simulation so that the system can be designed in such a way that its highest and lowest pressure level variations would be within allowable limits.

4. Upset Condition

Upset Condition is abnormal or unexpected operating conditions, such as sudden changes in flow rate, fluid properties, and failure of valve that happens with the system. These conditions can cause significant changes in pressure pulsation, leading to damage and failure of the pump and its components.

Many factors, such as human error, process changes, etc., could cause these conditions. That’s why analyzing and understanding potential upset conditions in a system is vital in pulsation analysis. Consequently, a system can be designed to be more resilient to these conditions and have minimal effects on the pump and piping system.

5. Operating Condition

The operating condition is the specific condition under which a system is operated, such as flow rate, fluid property, and system geometry. These conditions can affect the pulsation in the system. For example, a high flow rate can lead to high-pressure pulsation than a low flow rate. Also, fluid properties, such as viscosity, can lead to pulsation issues in the pump.

Therefore, it is vital to analyze and understand operating conditions in the pulsation analysis of the system. So, the system can be designed to have minimum pulsation effect under certain operating conditions.

Conclusion

Pulsation analysis of the reciprocating pump is crucial to maintaining and optimizing the performance of the pump and piping system. Also, you should constantly monitor and inspect the pump to ensure that it operates effectively and prevents potential issues caused by pulsation.

An experienced piping analysis consultant can help you execute all these easily.

Mechartes provides advanced engineering and simulation services for pulsation analysis to optimize and improve the performance of the pump and piping systems. Our additional services for piping systems include hydraulic analysis, noise vibration in the pipe system, pressure vs. frequency, mechanical vibration, stress, etc.

Talk to our experts to learn more!

Share

Share  facebook

facebook