In the rapidly evolving world of industrial machinery, efficiency is not just a desirable trait—it’s a necessity. With the increasing complexity of systems and the relentless demand for high performance, companies are constantly seeking ways to optimize their operations.

One such method that has proven to be incredibly effective is leveraging Finite Element Analysis (FEA) consulting.

This article explores how companies like Mechartés, with their team of Pipe Stress Analysis Consultants, are using FEA to help their clients maximize efficiency and achieve their operational goals.

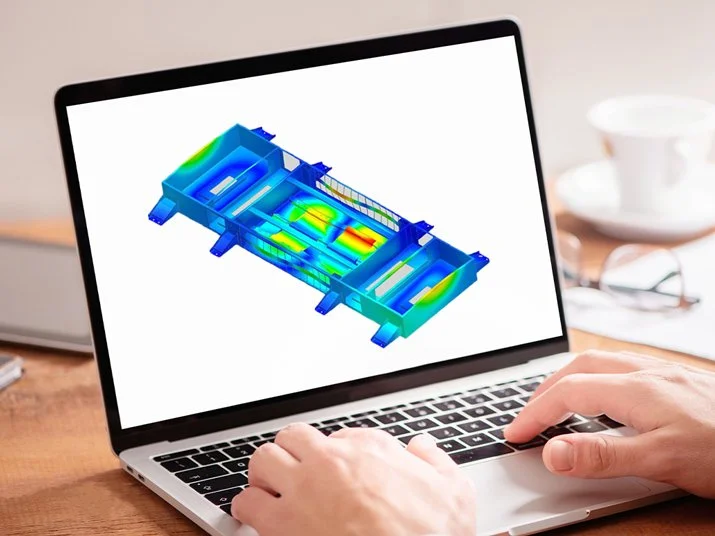

Finite Element Analysis (FEA) is a digital technology that forecasts how a product will respond to real-world forces such as vibration, heat, fluid flow, and other physical impacts. It provides insights into whether a product will fail, degrade, or function as intended.

Despite being termed as ‘analysis,’ it is primarily employed during the product development phase to anticipate the product’s performance during its actual use.

The role of Pipe Stress Analysis Consultants in this process is crucial. They use FEA to accurately predict the performance of a product, particularly piping systems, under a wide range of physical conditions, reducing the need for costly and time-consuming physical prototypes.

Finite Element Analysis Software Market size was valued at USD 4,787.2 Million in 2021 and is projected to reach USD 14,992.0 Million by 2030, growing at a CAGR of 14.04% from 2023 to 2030.

The process of Finite Element Analysis (FEA) involves dissecting a real-world object into numerous (ranging from thousands to hundreds of thousands) finite elements, akin to small cubes. These elements are then subjected to mathematical equations to anticipate their individual behaviors. A computer system then aggregates these individual behaviors to project the overall behavior of the actual object.

Mechartés, an established name in the field of engineering solutions, has been at the forefront of providing FEA consulting services. Our team of Pipe Stress Analysis Consultants, with a strong focus on Computational Fluid Dynamics (CFD), HVAC analysis, Piping Analysis, and Acoustic Analysis, has been assisting architectural firms, large-scale construction companies, and other entities involved in the construction of large structures.

Mechartés’ FEA consulting services offer a comprehensive approach to problem-solving, providing clients with actionable insights and solutions tailored to their specific needs.

Mechartés’ services extend beyond just providing solutions. We are committed to helping their clients understand the intricate details of their operations, such as the flow of air, heat, cooling effects, water pressure, wind analysis, and heat production due to pedestrians/people’s movement around the structures.

Our expansive expertise in FEA and other analysis methods has made them a trusted partner for companies looking to optimize their operations and maximize efficiency.

In the realm of FEA consulting, one role that stands out is that of Pipe Stress Analysis Consultants. These professionals play a crucial role in ensuring the safety and efficiency of piping systems in various industries. They analyze the stresses in the pipes under different conditions to ensure they are within acceptable limits, thereby preventing failures and shutdowns.

Mechartés offers this vital service with its team of experienced Pipe Stress Analysis Consultants. We use advanced tools and techniques to perform detailed analyses and provide actionable insights to our clients.

This not only helps in maintaining the integrity of the piping systems but also in optimizing their performance. Mechartés’ team of Pipe Stress Analysis Consultants uses advanced tools and techniques, including FEA, to ensure the safety and efficiency of piping systems in various industries.

To understand the real-world impact of these services, let’s delve into one of our case studies on surge analysis. It is a testament to Mechartes’ expertise and the value they bring to their clients. It also underscores the importance of services like FEA consulting and Pipe Stress Analysis in maximizing efficiency in industrial machinery.

The objective and outcomes of this analysis were as follows:

Objective: The primary goal of this analysis was to ensure that the pressures in the piping network were within the acceptable criteria for the most severe cases of surge scenarios.

Methodology: The study involved modeling and analysing the pipeline and its components. These components included valves, area change, expansion joints, elbows, and tee junctions.

Outputs: The analysis yielded several important outputs:

Pressure contours in the complete network.

Comparison of pressure inside the pipeline with vapor pressure.

Hydraulic grade and air/vapor volume near pump discharge/suction side.

Graphs near to pump show pressure gradient/peak during shutdown and start-up conditions.

This case study demonstrates the technical prowess of Mechartés and highlights the practical implications and benefits of such analyses in real-world scenarios.

In the quest for efficiency in industrial machinery, leveraging Finite Element Analysis consulting has emerged as a game-changer. It allows companies to predict and address potential issues, optimize their operations, and ultimately maximize efficiency.

Mechartés, with its team of Pipe Stress Analysis Consultants and a wide range of services, including FEA, CFD, HVAC analysis, and Pipe Stress Analysis, has been instrumental in helping companies achieve these goals.

In the end, the goal is clear: to create industrial machinery that is not only efficient but also reliable, safe, and effective. With the help of Mechartes’ Finite Element Analysis consulting, this goal is well within reach.

Contact us to learn more.