How do you learn and train for fire safety? By setting things on fire, of course! But not just any fire – a fire simulation chamber that mimics the real thing. These chambers are amazing tools for studying fire dynamics and testing human resilience in dangerous situations.

However, constructing and maintaining such enclosures takes a lot of work. Top-tier structural analysis services are required to guarantee they can endure the intense heat, pressure, and gas flow generated by the simulations. How do they do it? By using advanced software tools like Finite Element Method (FEM) and Fire Dynamics Simulator (FDS) to model how the structure reacts to the fire’s thermal, mechanical, and chemical effects.

This article will explore some key aspects of providing structural analysis services for large-scale fire simulation chambers.

Engineers and scientists are able to test and assess the effectiveness of fire-resistant materials, analyze and enhance fire safety and preventive methods, and ensure compliance with and updates to fire protection legislation with the use of fire simulation chambers.

Here are some important points in detail:

Engineers can use cutting-edge structural analysis software like PROFIS Engineering Suite, Fire Dynamics Simulator (FDS), and Consolidated Model of Fire and Smoke Transport (CFAST) to determine if the chamber will withstand the extreme temperatures, pressures, and dynamic forces generated by the simulations.

To ensure the chamber’s dependability and safety, finite element analysis (FEA) can describe the complex thermal and structural interactions occurring within the chamber.

The chamber’s capacity to simulate real fire conditions is analyzed using structural analysis services to assure accurate testing. Computational Fluid Dynamics (CFD) models allow engineers to study gas flow patterns, temperature distributions, and fire spread to determine the fire chamber’s efficacy.

Durable materials, from concrete to treated wood and beyond, each have their own characteristics in terms of heat conductivity, expansion, combustibility, and insulation.

FEM, FDS, heat transfer analysis, stress analysis, and fatigue testing are only some of the structural analysis methodologies used to examine the behavior of these fire-resistant materials and reveal useful insights for fire safety and protection.

This includes heat transmission, gas flow, combustion, smoke movement, thermal stresses, deformation, and failure, all of which may be efficiently modeled to predict how materials would react in a fire.

Important standards for fire safety and drills are published by the National Fire Protection Association (NFPA). Engineers may verify that the chamber complies with safety regulations and develop ways to strengthen it by evaluating its structural integrity.

Engineers model the fire and smoke dynamics in the chambers with great accuracy using software like Fire Dynamics Simulator (FDS) and Smokeview (SMV) or FDS-SMV2. In addition, non-destructive testing techniques, such as ultrasound and thermal imaging, emerge as a crucial safety measure, rigorously revealing any vulnerabilities or structural defects inside the chamber, guaranteeing its unwavering robustness and unwavering devotion to safety.

Structural analysis services ensure the long-term viability and safety of training facilities, boosting fire departments’ effectiveness. In order to determine how well the chamber can withstand repeated loading and extreme conditions, dynamic structural analysis and fatigue tests are performed.

Some of the firefighter training advancements courses in this regard are:

NFPA 1700, Guide for Structural Fire Fighting, is a document that connects fire dynamics research to response strategy, tactics, and best practices for firefighters attempting to control fires within a structure.

NFPA 1700 online training is a free online course that teaches firefighters safer and more effective ways to handle fire incidents involving modern-day materials and contents. The course uses interactive modeling of residential structural firefighting with simulated training scenarios and coaching throughout exercises.

Mechartes is widely recognized as the best in the business when it comes to structural analysis services for large-scale industrial fire testing facilities. When it comes to designing and optimizing buildings that can endure high temperatures, high pressures, and both, customers benefit from Mechartes’ experience of fire safety.

Mechartes employ state-of-the-art simulation tools and techniques to study the thermal, mechanical, and chemical behavior of structural materials and components. We pay close attention to every detail to ensure the highest quality and safety in our fire simulation chambers.

As an illustration of Mechartes’s far-reaching effect, we will examine how the knowledge of structural analysis services for large-scale fire simulation chambers led to significant advances.

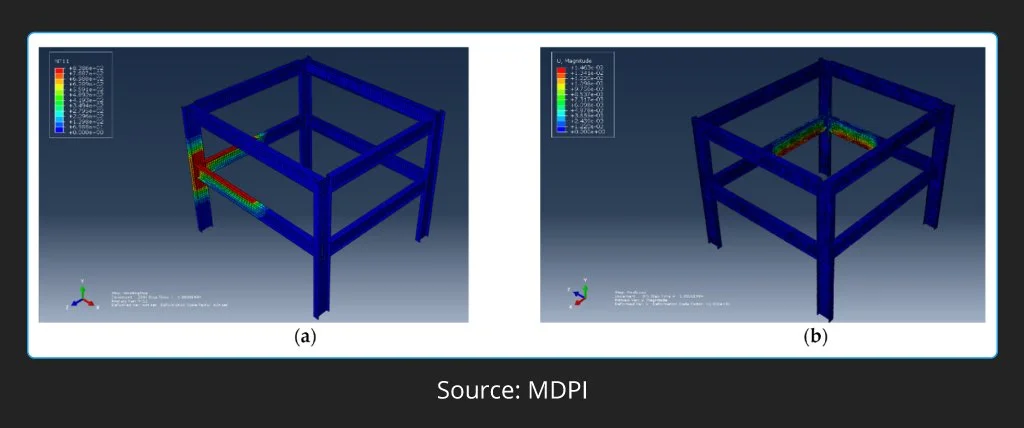

With unmatched expertise in structural analysis, Mechartes took charge, utilizing the powerful ANSYS software to perform finite element analysis (FEA) on the fire chamber structure. But the dedication didn’t stop there!

Mechartes went the extra mile, conducting a meticulous parametric study to uncover the most optimal design parameters for the structure. The culmination of their efforts resulted in nothing short of excellence, elevating the fire chamber’s safety and performance to new heights.

This study aimed:

To assess the maximum stresses on the main force-resisting members for wind and thermal loads.

To focus on the platform’s structural elements, including columns and plates, using suitable Stainless Steel grade (SS-304) material.

The analysis considered various loads individually and in combinations, such as static weight, wind loads, and thermal loads. Mechartes helped the client achieve the following results:

The analysis considered individual and combined loads, such as static weight, wind loads, and thermal loads.

Structural modeling included 1D beam elements for C Section beams, Box channel beams as support structures, and 2D Shell Elements for the platform with a uniform distributed load.

Recommendations included adding channels for platform strengthening and C-Channels with additional 3″x3″ gusset plates for improved weld strength.

Optimal Expansion Bolts were proposed with suitable locations and plate sizes.

Grade 43 N/m concrete was identified for use in the fire simulation chamber.

You can read the case study below to learn more about Mechartes’ comprehensive modeling and analysis.

The use of fire simulation chambers and complicated engineering systems in structural analysis services are crucial in assuring building safety, evaluating structural integrity, and achieving regulatory requirements.

With its cutting-edge technology and highly skilled engineering staff, Mechartes has established itself as a market leader in the field of structural analysis. Objective evaluations of design performance, innovative solutions to fire threats, and strict adherence to all relevant rules and norms are all part of the package when you hire us.

Customers seeking reliable structural analysis and fire simulation solutions will find no better alternative than Mechartes.

Contact Us to learn more!