When designing, engineers frequently need to address questions about heat transfer. It is crucial to use the most appropriate tool for your task. Heat transfer mechanisms in the components you are designing dictate the approach to be used: conduction, convection, radiation, or mostly a combination of all three.

You will also be influenced by how much accuracy you are willing to accept. We will help you examine how and when to use Computational Fluid Dynamics (CFD thermal analysis) and Finite Element Analysis (FEA) for heat transfer issues. To put it simply, when to use which thermal analysis? Before addressing that, we will start with some basics – Thermal Analysis.

In general, thermal analysis determines when a substance undergoes physical changes when heated or cooled under specific temperatures. Different techniques are used to study different types of changes. Thus, material characteristics can be evaluated with various methods or by combining those, depending on the purpose.

Thermodynamic analysis has become an integral part of many modern design processes. The temperature level affects the strength and performance of most fluid flows, parts, materials, and structures. However, analytical calculations or physical measurements often do not provide the same level of information as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD).

Let us examine both ways of thermal analysis so that we can determine when to use each.

Research & development, quality control, failure analysis, and regular designs – all require thermal simulations. In addition, batteries for electric automobiles, electronic components on PCBs, or solar boilers, which generate heat are subject to external heat sources. As a result, they can all benefit from advancements in heat dissipation and temperature management.

As part of thermal analysis, fluid flows and heat transfer between fluids and solids are examined. A lot of these analyses aid in assessing chemical and pharmaceutical processes. Few even help to develop innovative renewable energy projects.

Computational fluid dynamics or CFD analysis and Finite Element Analysis (FEA) are typical tools used for thermal analysis. Let’s break it down further for individual analysis.

A thermal analysis utilizing FEA can investigate the transfer of heat between solids or within solids. Convection, conduction, and thermal radiation are examples of heat transfer mechanisms that can be calculated. However, this is because the software does not factor in convection and thermal radiation, which the analyst defines.

An FEA is most useful when it can be assumed that the coefficient of heat convection is constant across the part surface or known precisely. FEA applications to thermal analysis can also determine thermal expansion and structural stresses associated with thermal gradients within the part.

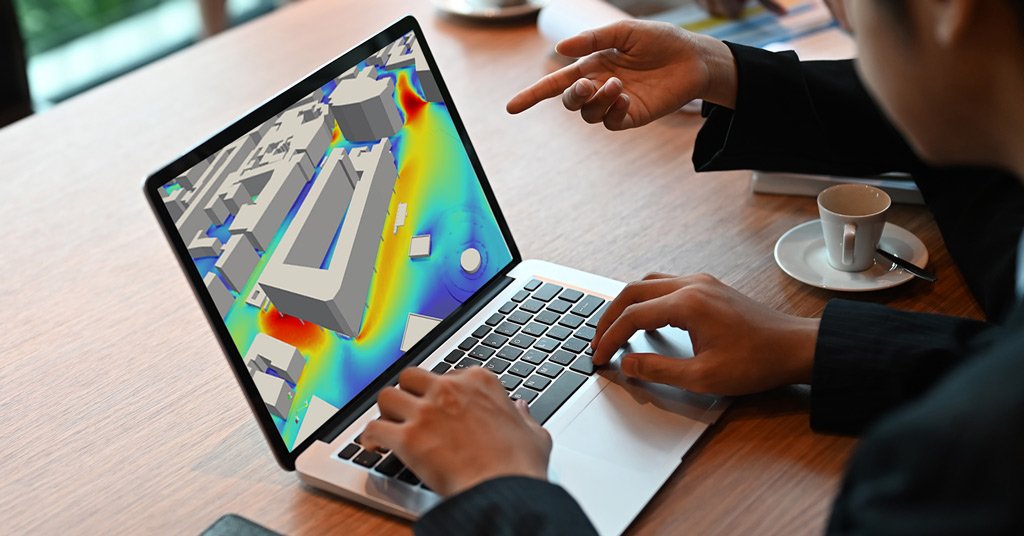

Thermal analysis can be performed using CFD analysis, which calculates the heat transfer between a fluid and solid, along with convection within the surrounding fluid.

The software calculates convection between a fluid and one or more solid parts and can eliminate uncertainties about the heat transfer coefficient by analyzing the fluid flow accurately. The local velocities and turbulence along a part’s surface, together with the fluid’s temperature-related properties, are all calculated by CFD analysis with high precision to help with convective heat transfer.

Upon expanding the acronym, the real difference will become evident. CFD stands for Computational Fluid Dynamics. FEA / FEM stands for Finite Element Analysis / Method. Now that we understand that the former is a method while the latter is an application, the distinction is clear. FEM is similar to finite volume, finite difference, and spectral methods for solving partial differential equations.

An implicit reference to a CFD simulation is a fluid dynamics simulation based on the Finite Volume Method. One can also conduct CFD simulations utilizing FEM or other methods, but this is less common than FVM. Almost all commercial and open-source code, such as Fluent and Open FOAM, use FVM as their underlying solving algorithm.

Computational mechanics problems are most often solved through the use of Finite Element Analysis (FEA). FEA is one method used to solve CFD problems – but it is often referred to as an “unstructured grid method” rather than the traditional “structured grid” used to solve finite difference problems.

The way the solution propagates to different domain regions over time can determine whether a partial differential equation is elliptic, parabolic, or hyperbolic. For example, problems involving time-dependent heat transfer are parabolic, but most structural analysis problems are elliptic. Therefore, it is often beneficial to apply an approximate parabolic or elliptic equation instead. For instance, they are assuming that the speed of sound is infinite when the speed of sound in the material is larger than the structure’s response.

There is no neat mathematical classification of fluid flow solutions — different assumed parts of the domain exhibit elliptic and hyperbolic behavior. In the absence of a solution, the boundary between the types of behavior cannot be established. So, even when FEM is used in CFD analysis, they differ in several essential ways from FEA methodologies used for structural analysis.

Are you still confused with FEA vs. CFD? We at Mechartes are here to assist you and offer advice. Our engineering team at Mechartes has extensive experience in performing heat analyses with FEA and CFD. If you’re interested in learning how we can solve your thermal problems, contact us today. We can make you an offer or schedule a meeting to discuss your business needs.