Engineers in the oil and gas sector require the necessary tools & resources to precisely comprehend and forecast the physics of multiphase flows.

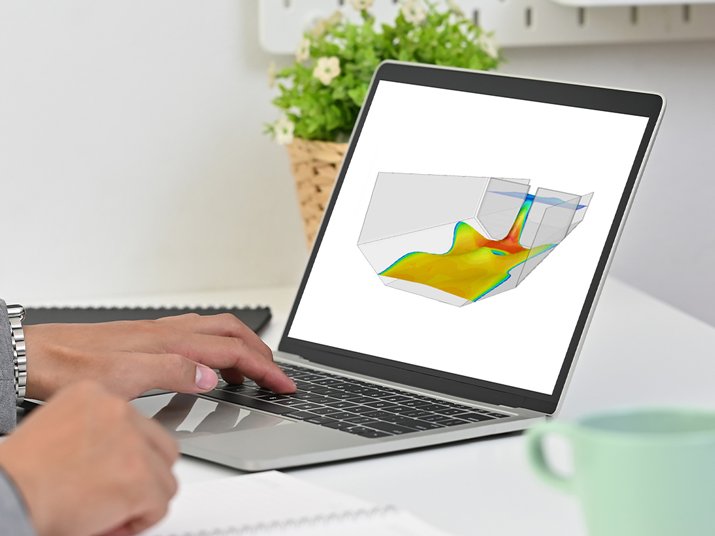

Computational fluid dynamics (CFD) and its simulation techniques are being used increasingly by engineers and design experts across industries to simulate complex processes with different states of matter.

Computational fluid dynamics in multiphase flow helps to evaluate phenomena such as liquid films, droplet transport, slug flow, and bubbly/scattered flow regimes by merging models.

In this article, we will discuss the multiphase flow model in CFD and its applications in the Oil and Gas Industry.

What Is the Multiphase Flow Model in Computational Fluid Dynamics

In a multiphase flow, simultaneous interaction of one or more materials in different phases is involved. The simulation of a multiphase flow is used to study the transfer of mass, momentum, and energy between phases in accordance with conservation laws.

Multiphase flows can have several flow characteristics depending on the system (through which they are flowing), the velocity, fluid characteristics, and the relative volume fractions of each phase present at any point in the system. Computational fluid dynamics has created a variety of methods to model the complexity of such flows.

Application of CFD for Multiphase Flow Simulation in the Oil and Gas Industry

Analysis of multiphase flows, particularly in the oil and gas industry, is one of the emerging areas where computational fluid dynamics is emerging as a reliable tool. Here are some crucial areas in the oil and gas industry where CFD analysis multiphase flow can prove to be essential:

1. Predict Impact of Solid Particles in Pipelines

In the majority of industrial processes that involve fluid flows, one can find the occurrence of solid particles. Before reaching any process equipment in the oil and gas industry, sand particles are routinely produced and transported via pipelines along with crude oil and natural gas.

Using Computational fluid dynamics analysis in this multiphase flow, you can predict the impacts of these particles on the inner wall of the pipes, fittings, valves, and other pumping devices, wearing down these facilities.

2. Reduce Erosion Damage

In order to reduce the damage caused by erosion in equipment, CFD consultation is necessary to estimate various effects, including solid erosion damages.

Erosion can lead to pressure loss or, in the worst circumstances, equipment failures. CFD multiphase flow approaches can be used to analyze the impacts of solid particles on pipe bends (or elbows) in order to predict erosion, thus, take measures to prevent it.

3. Design Optimization

Multiphase CFD flow analysis can be used on a variety of designs and components like drilling hydraulics and hole cleaning optimization. Not only this, but it is also useful in wellbore stability analysis, cutting transport in the wellbore, and flow optimization via oil and gas wells.

The technology can help in improving equipment design and meet environmental concerns by reducing failure that could result in a potential oil leak, operational issues, production loss, and significant financial losses.

Computational fluid dynamics can be used in designs in the following ways:

-

Drill Tool Design

CFD simulation is also employed for drill tool design to ascertain the impact of multiphase flow on the cutting concentration and pressure drop profiles, among others. This helps to reduce pressure losses and annular geometry while delivering an economical drilling tool design that’s efficient in the long run.

-

Flow Separator Device

The portion of the solid particles that contribute to equipment erosion in pipelines and other sites can be identified using the multiphase CFD analysis.

The CFD simulations aid in the designing of flow separators that block the transport of the solid particles based on the data acquired, so minimizing the harm caused by the same.

-

Offshore Construction Design

Some equipment in offshore construction is continuously exposed to the water in the ocean. These offshore structures are bombarded with salts and minerals present in the water, which can cause corrosion failure. Multiphase CFD flow analysis is used here to design various protective equipment for offshore structures in order to reduce corrosion and its influence on the same.

-

Design Downhole Tools

Experts use multiphase CFD analysis to understand the physics related to downhole fluid flow, preserve the safety of the downhole tools, and improve oil and gas production.

Multiphase CFD analysis is used to forecast two-phase flow behavior: gas-liquid and liquid-liquid. This ensures uninterrupted and secure transit of production fluid from the downhole to the processing facilities. This analysis secures data such as flow patterns, liquid holdup, and pressure drop in complex flow conditions, which is then optimized for the design of drilling equipment to reduce the same.

Enabling Businesses With Industrial Expertise

There is an increased need to enhance production while minimizing any delays or losses. Multiphase CFD assessments ensure that there are no deadly environmental catastrophes in the oil and gas industry while extending the life of the equipment needed.

Mechartes’ CFD services for Multiphase flow analysis help in amplifying the success rates of the machinery and its components. With our expert solutions, businesses can avoid potential damages to equipment and maximize ROI with efficiency and safety.

Check out our website for more details, or get in touch to discuss your business requirements today!

Share

Share  facebook

facebook