Imagine breathing in fresh air that is cleaner than the air outside. Sounds impossible, right? Not with fresh-air plant rooms.

These rooms are part of HVAC systems that provide fresh air to buildings. However, indoor air can be much more polluted than outdoor air, affecting the health of people who spend most of their time indoors. According to the EPA, Americans are indoors 90% of the time, where indoor pollutant levels can be two to five times higher than outdoor levels.

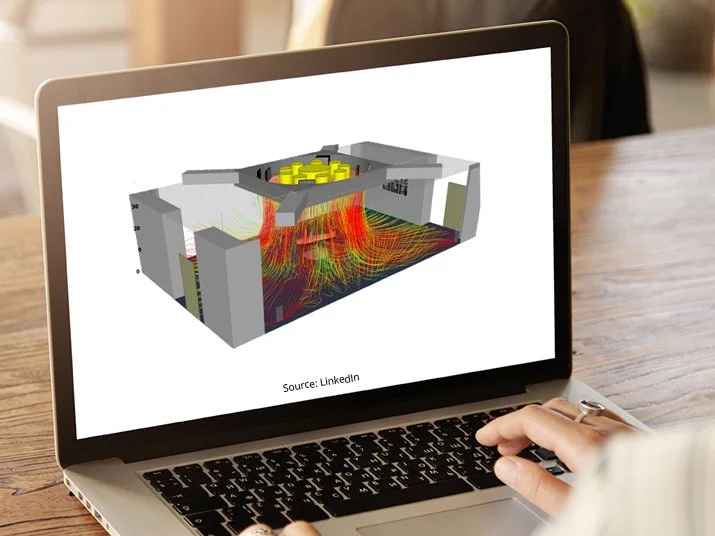

This is where we need computational fluid dynamics (CFD) to improve fresh-air plant rooms. CFD is a tool that can simulate and analyze airflow in complex environments.

In this article, we will explain how CFD consultancy can help design better fresh-air plant rooms and enhance indoor air quality (IAQ).

CFD is a numerical method that uses computers to solve the governing equations of fluid mechanics and thermodynamics. It can provide detailed and accurate information about flow behavior, temperature distribution, pressure distribution, and other physical quantities that are difficult or impossible to measure experimentally.

CFD consultancy services use this approach to simulate and analyze fluid flow and heat transfer in various engineering applications.

Some of the factors considered while designing for CFD by CFD consultancy services for effective air management in fresh air plant rooms are:

The geometry and configuration of the fresh air plant room and the HVAC system, including the location, size, shape, and orientation of the fans, ducts, vents, filters, heaters, coolers, dampers, valves, sensors, etc. This factor affects the CFD simulation’s flow domain and boundary conditions.

The properties and characteristics of the fluid and any other materials involved in the flow, such as density, viscosity, specific heat, thermal conductivity, emissivity, etc., affect the CFD simulation’s fluid dynamics and heat transfer.

The boundary and initial flow conditions encompass inlet and outlet pressures, temperatures, velocities, mass flow rates, turbulence intensities, and more, significantly influencing the flow behavior and convergence of the CFD simulation.

The physical phenomena and processes that affect the flow behavior and heat transfer in the fresh air plant room include turbulence, convection, radiation, diffusion, chemical reactions, multiphase flow, etc. This factor affects the physics models and numerical methods of the CFD simulation.

Some of the key CFD approaches for effective air management in fresh air plant rooms include:

CFD simulations can visualize and analyze the airflow patterns within the fresh air plant rooms. This provides valuable insights into the movement of air, identifying areas of stagnation, recirculation, and mixing inefficiencies. Understanding these patterns helps design better ventilation systems that evenly distribute fresh air throughout the building.

CFD can simulate the dispersion of contaminants, such as pollutants or airborne particles, within the plant rooms. Engineers can implement appropriate strategies to minimize exposure risks and maintain high indoor air quality (IAQ) by understanding how contaminants disperse and accumulate. Some software that does contaminant dispersion modeling are ADMS-Urban, Oizom, AERMOD View, etc.

CFD simulations enable the mapping of temperature and humidity distribution within the plant rooms. This information aids in designing efficient HVAC systems that maintain optimal comfort levels for building occupants while conserving energy.

CFD can assess the thermal comfort of occupants within the fresh air plant rooms. Engineers can optimize the HVAC system settings by predicting temperature variations and drafts to ensure a pleasant indoor environment. CBE Thermal Comfort Tool for ASHRAE-55, ThermoAnalytics Human Thermal Comfort Software, and Human Thermal Model FIALA-FE are some softwares that analyze thermal comfort.

CFD simulations are crucial in designing and optimizing HVAC control strategies. This ensures that the fresh air plant rooms respond dynamically to changing environmental conditions and occupant demands, maintaining a healthy and comfortable indoor environment.

When it comes to efficient air management, Mechartes stands out as an innovator committed to improving IAQ and advancing green building practices. Mechartés is widely recognized as a frontrunner among companies offering CFD consulting services due to its pioneering spirit and dedication to its client’s success.

Mechartes excels in detailed environmental analysis and CFD simulations. Their advisory services precisely identify optimal airflow patterns, temperature distribution, pressure dynamics, and other factors impacting IAQ and energy efficiency. As an example of Mechartés’s far-reaching influence, we’ll look at how his work altered the layout of rooms for fresh air plants.

Mechartes, specializing in CFD consultancy services for diverse engineering applications, boasts a proven track record of delivering high-quality and innovative solutions to its clients. Here is one case study where Mechartes utilized CFD simulation to analyze the airflow and temperature distribution in Dubai International Airport’s fresh air plant rooms in 2017.

The objective was:

To optimize the design and performance of the ventilation system

To ensure adequate fresh air supply for the airport.

The case study presents the CFD simulation’s geometry, boundary conditions, meshing, and results. The results show that the CFD simulation captured the complex flow and thermal behavior of the fresh air plant rooms. The results also show that the ventilation system met the design criteria and provided uniform and efficient air distribution.

To learn more about modeling and analysis done by Mechartes here, read the case study below.

Effective air management in fresh-air plant rooms has become a crucial consideration in pursuing healthier and more eco-friendly indoor spaces.

By harnessing Computational Fluid Dynamics (CFD) consultancy services, engineers can fine-tune airflow patterns, temperature distribution, and ventilation systems, improving indoor air quality (IAQ) and energy efficiency. It also plays a key role in visualizing and analyzing intricate airflow patterns and evaluating thermal comfort and contaminant dispersion.

Leading the charge in this endeavor is Mechartes, a Leading CFD, FEA, Piping and Acoustic Analysis company renowned for its innovative and wide-ranging CFD consultancy services. Our expertise in planning space-saving fresh air plant rooms and delivering high-quality solutions has earned them industry-wide recognition.

Contact Us today!