This article will address the importance of Computational Fluid Dynamics (CFD) analysis for primary and secondary contact tanks in SWTPs (Sewage Water Treatment Plants). It will provide an overview of the process and discuss how CFD can help to optimize the design.

The Importance of CFD Analysis in SWTP Designs

We can use CFD analysis software to find the optimal SWTP design. It can test different plant configurations and determine their performance under various conditions. This saves time and money for engineering firms, as they can test many different designs without actually building them.

CFD analysis is a powerful tool that can be used to analyze the flow and pressure in complex systems, like SWTP designs, helping engineers make more informed decisions.

It can be used to simulate the real-world conditions of the plant. It can analyze various designs, including turbomachinery designs, SWTP, heat exchanger designs, aircraft component designs, and many more.

Primary and Secondary Contact Tanks in Sewage Water Treatment Plants

The contact tanks are an essential part of the sewage water treatment plant as here the water is mixed with additives to remove as much of contaminants as possible. To efficiently remove impurities, it’s essential to administer additives carefully. The mixing process also helps maintain a safe pH and alkalinity level in the water.

The contact tanks are also used as supplementary storage. In the case of a power loss, SWTP staff can use the contact tanks to store up to 10 days’ worth of treated water in the primary tanks.

There are two contact tanks in an SWTP, primary and secondary, which are interconnected. When the water levels in the contact tanks start to decrease, disinfectant is injected into the primary tank and then mixed with water until it reaches a sufficient concentration. The design of a contact tank is an inflow or suction port on one side of the tank and an output or discharge port on the other. The inflow and the discharge ports are connected by a pipe that has a non-return valve (N/R valve). The disinfectant is delivered to the tank through this N/R valve. The function of the secondary contact tank is to dilute the disinfectant as per the water requirement of each batch.

Importance of CFD Analysis for Contact Tanks in SWTPs

CFD analysis is a simulation technique used to model the flow of fluids, which makes it an essential tool in predicting the behavior of fluids involved in many different industries, such as oil, gas, water, and sewage treatment plants.

The plant uses large tanks to collect wastewater and pollutants before treating them with various chemicals and bacteria. CFD analysis can determine how much sewage needs to be pumped into the tanks at a given time, what kind of chemical reactions will happen inside the tank, how long it takes for these reactions to complete, and how much sludge will form inside the tank over time. This data helps focus on individual units of the system to increase cost-effectiveness.

CFD analysis helps engineers optimize their products’ design and performance by predicting their designs’ airflow and heat transfer.

The analysis will calculate the flow field through the object and predict the pressure and temperature distribution in the area of interest. In addition, it will provide information about how heat is transmitted to other objects that are subjected to different temperatures. The importance of CFD analysis in designing SWTP’s Primary and Secondary Contact Tanks cannot be underestimated.

CFD Analysis for Primary and Secondary Contact Tanks in Sewage Water Treatment Plants

This article aims to investigate the effect of CFD analysis on the performance of Primary and Secondary Contact Tanks in SWTPs. The purpose is to analyze the flow pattern, heat transfer coefficient, and pressure drop distribution in sewage treatment plants and then to identify the significant constraints.

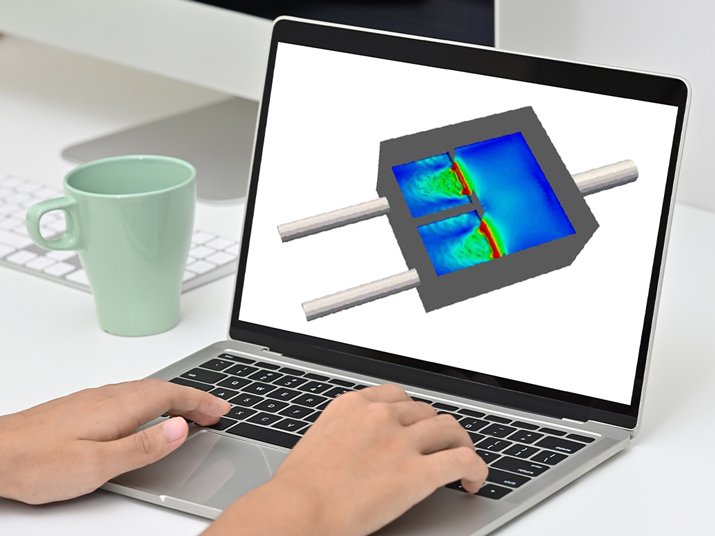

Regarding contact tanks, the flow patterns created by interactions between additives are essential for optimization. CFD simulations of contact tank design alternatives can be used to accurately model the residence and contact time for the range of flow and water level scenarios during the disinfection process.

CFD simulations have proven to be an excellent tool for engineers to optimize contact tank design. These simulations allow engineers to evaluate the performance of their design alternatives and identify the best design as per their needs. CFD integrated into the design process can be used to:

i) Predict contact times

ii) Identify dead zones in the tank

iii) Prevent overfilling

iv) Identify potential leaks

v) Determine the quality of the air in the tank

Final Thoughts on Why CFD Analysis Is Crucial for SWTP Contact Tanks

CFD analysis is the key to determining the performance of an SWTP contact tank. It can be used to predict the behavior of fluids in a tank and the effects of various parameters, such as fluid properties, tank geometry, and boundary conditions which is crucial for ensuring that the tanks are functioning well.

CFD analysis uses computational fluid dynamics (CFD) simulation software to solve complex fluid flow problems that cannot be solved by analytical methods alone. One can identify the pressure drop that occurs across various tank components and also predicts the performance of a tank as it relates to heat transfer using CFD analysis. This also helps ensure the structural integrity of tanks and avoid failure-prone areas when designing tanks.

Need to know more about this analysis method? Head over to our website or speak to a CFD and FEA specialist.

Share

Share  facebook

facebook