1. Introduction

The performance of chillers can be adversely affected by insufficient intake of fresh air and the spacing between the chillers. This can lead to re-circulation of hot air into the chiller inlets from the outlet of the chillers.

CFD Analysis can assist engineers to evaluate the performance of the chillers during the design / construction stage and to take necessary mitigative measure to eradicate design issues and to improve the performance.

It can also be used during the operational stage to mitigate any issues in the operation of the chillers.

2. Objective

The main objective of the CFD analysis for the Project owners/contractors/design consultants is to check the following:

-

To study whether the “hot air rejected from condenser fan outlets of each chiller” is entering into the “inlet of the Chiller” or not, and if so, how severe is the re-circulation of air is in these chillers.

-

To study the velocity & temperature profiles around the Chillers.

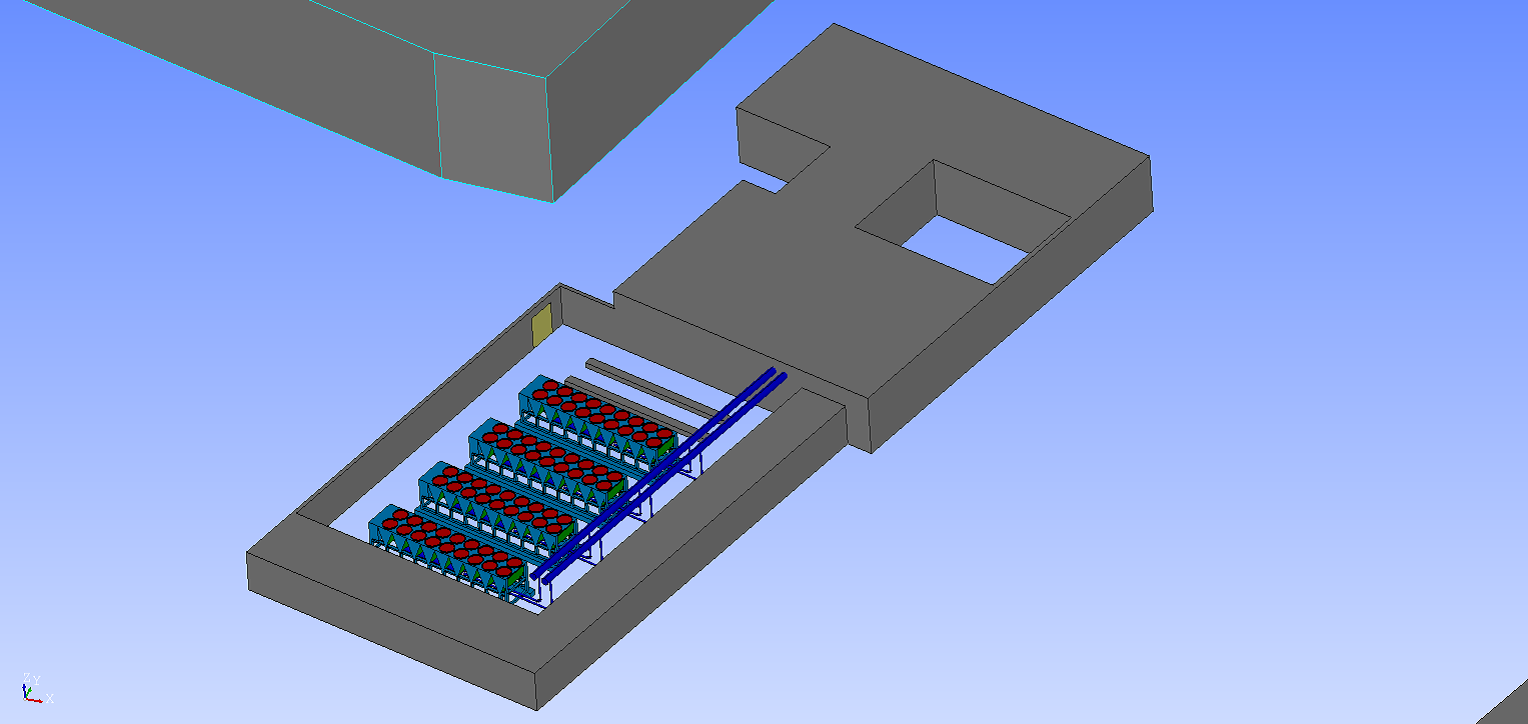

3. Modelling

Per the inputs and design drawings received, we prepared a detailed 3D model of the complete Chiller Yard in the CFD Software.

A CFD Wind tunnel is created by modelling the nearby buildings. In the Chiller yard all the obstructions including the major pipes, wall obstructions, equipment’s were also modelled along with the Louver details.

Appropriate boundary conditions, including the intake, discharge temperature and velocity from the chillers were considered for the study. The wind and ambient conditions were chosen for the work per the project requirement and site location.

4. Conclusion

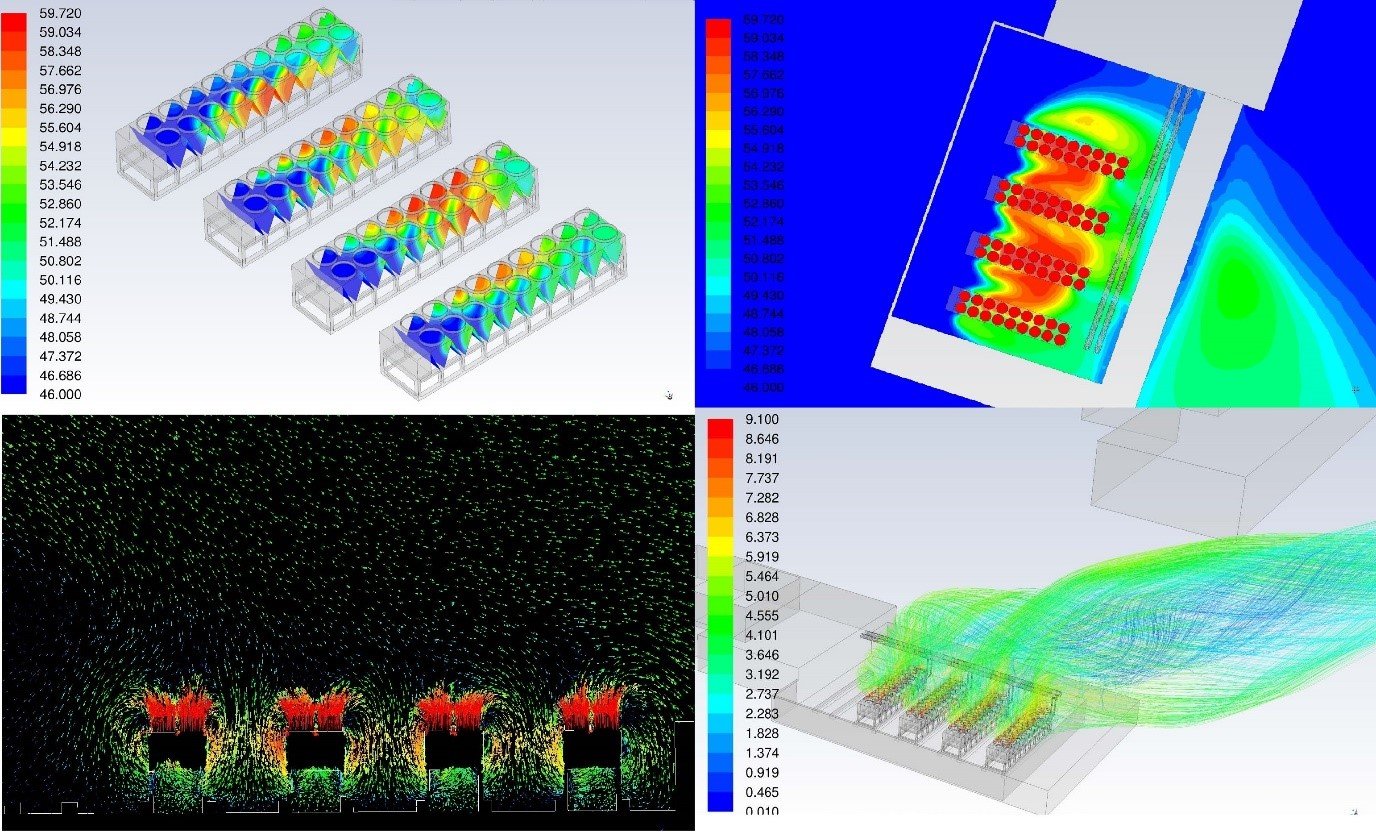

Upon completion and approval of the 3D model report, a steady-state CFD Simulation was performed to study the velocity, Dry Bulb Temperature and % of re-circulation on each inlet were studied.

It was observed from the study that there was a considerable increase in temperature at the inlets of the chiller yard which had an impact on the performance. The recirculation calculations found that nearly 30.5 to 44.6 % of air recirculated.

This also resulted in increase in Dry Bulb temperature which was varying between 50.18 to 52.12 °C, which indicates that the temperature of air entering the chiller units is higher than the atmospheric temperature of 46°C by a maximum of 6.12°C. This was mainly due to the movement of hot air from outlets towards the inlets of the chiller.

5. Recommendation

To prevent the effect of high-temperature outlet discharge air moving toward the inlets of chillers increase in louver openings along with the appropriate stack height and canopy between the chillers were provided.

Multiple iterations were carried out with the modifications which clearly showed a considerable decrease in the re-circulations improving the performance of the Chiller yard.