1. Objective

The main objective of the CFD steady state simulation is to design the tank internals so that the oil concentration and solid concentration in the effluent water outlet is less than the design criteria (as specified by the end-user).

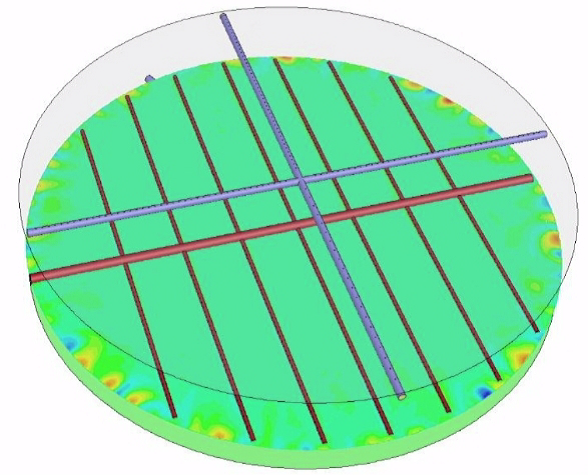

The internals are designed such that the incoming mixture gets uniformly distributed throughout the tank and all the process parameters are achieved in the normal operation of the tank.

2. Modeling & Analysis

The domain to be analyzed is divided into small volumes in CFD and equations are solved for these volumes using numerical methods. The fluid domain is meshed with tetrahedral elements with varying size functions for small slots. For the inlet Distributor, fine unstructured meshing was employed with a mesh size of 0.1 m.

The total numbers of mesh elements are generally in millions with more than 4 million tetrahedral elements and around 3000 pyramidal elements. Reynolds numbers on gravity separation are used for distributor internal design.

The oil droplet trajectories are computed individually at specified intervals during the water phase calculation. Ansys Fluent predicts the trajectory of an oil particle by integrating the force balance on the particle, which is written in a Lagrange reference frame.

3. Outputs

-

Mass flow rates through the distributor slots.

-

Flow profile inside the tank.

-

Oil outlet particle size distribution in water outlet stream.

-

Average Retention time.

-

Oil in Water Concentration at water outlet.

-

Minimum oil particle size required for proper separation.

-

The oil collection rate at the oil skimmer and at produced water outlet.