1. Introduction

The existing large size double deck floating roof tanks are designed as per API 650. They were originally designed to handle crudes, mainly due to the additional crudes from the well, the TVP (True Vapour pressure) is expected to be increased.

Based on maximum temperatures of crude recorded in storage tanks over last several years, the maximum TVP value for corresponding RVP of different crude blends are to be evaluated by CFD studies.

The design suggestions and recommendations have to be provided based on the analysis outcome. Mechanical, structural and FEA studies to be carried out for the design modifications and suggestions proposed.

2. Objective

The objective of this scope is to study & propose various technically viable, safer and historically proven options to handle increased TVP.

Detailed technical evaluation of floating roof design has been carried out to understand the maximum / safe operating TVP of the crude storage tank.

The CFD analysis carried out as part of this study confirms that the vapour volume generated during day operation will present serious threats to the floating roof operation in terms of crude spilling, rim seal failure and increased possibility of fire hazard.

Problem Description

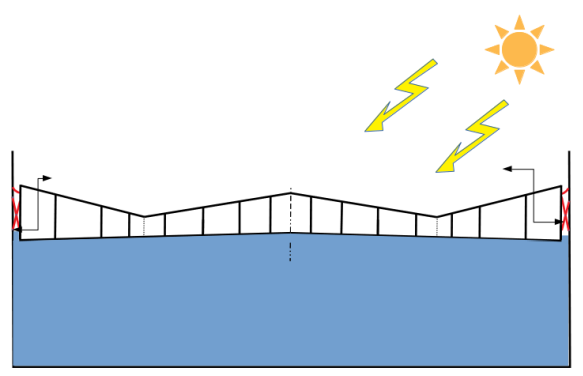

When floating roof type storage tanks are operated at high TVP conditions, where product TVP approaches closer to atmospheric pressure, it is generally understood that such a condition increases the emission of vapours from the external floating roof tank depending on the following conditions:

-

Liquid/product temperature

-

Vapour space above the product/liquid

-

Ventilation of the vapour space

-

Available liquid surface area

3. Modelling and Analysis

In the modelling and analysis of a CFD problem the general process for performing a CFD analysis is outlined below so as to provide a reference for understanding the various aspects of developing the solution for flow and thermal simulation of crude storage tank.

The processes include the following:

-

Model the Geometry and Flow Domain

-

Establish boundary conditions.

-

Grid Generation

-

Formation of the Simulation Strategy

-

Establish input parameters

-

Analysis & Simulation Runs

-

Post-Process the simulations to get results.

-

Reporting of results

4. Conclusion

-

Estimated the various modes of vapour formation inside the tank and calculated the quantity of vapour generated inside the floating roof tank during worst case scenario.

-

Evaluated the roof maximum surface temperature and crude surface temperature gain.

-

Venting calculations are performed to check and identify if current venting provisions on the tank are adequate.

-

The potential increase in emission for the proposed high TVP operations are calculated.

-

Modified the design drawings of the existing crude storage by incorporating the modifications and recommendations based on the analysis results.