1. Objective

The objective is to check the pipelines for operating & occasional loads. The piping network is then designed, that can withstand these loads & forces. Purpose of analysis is to determine the stresses, deflection & forces in pipelines in design as well as operating condition.

Based on results, various design modifications like flexible connectors, rigid anchors, additional supports, spring hangers etc. Stress analysis is conducted to come up with innovative design solutions that meet international codes like IBC, UBC, BS, ASME, FEMA, and API. Design of structural steel supports for piping systems are design using BS 5950 & ASCE.

To ensure the following parameters:

-

Static & dynamic thermal stress analysis for given load cases.

-

Analysis of occasional conditions such as wind loads & pressure relief valve loads.

-

Nozzle assessments including nozzle loads, stiffnesses and local stress analysis.

-

Assessment of design modifications including expansions joints, spring supports and more

-

Pipeline lifting assessments

-

Structural support Analysis and detailed design of piping supports

2. Modeling & Analysis

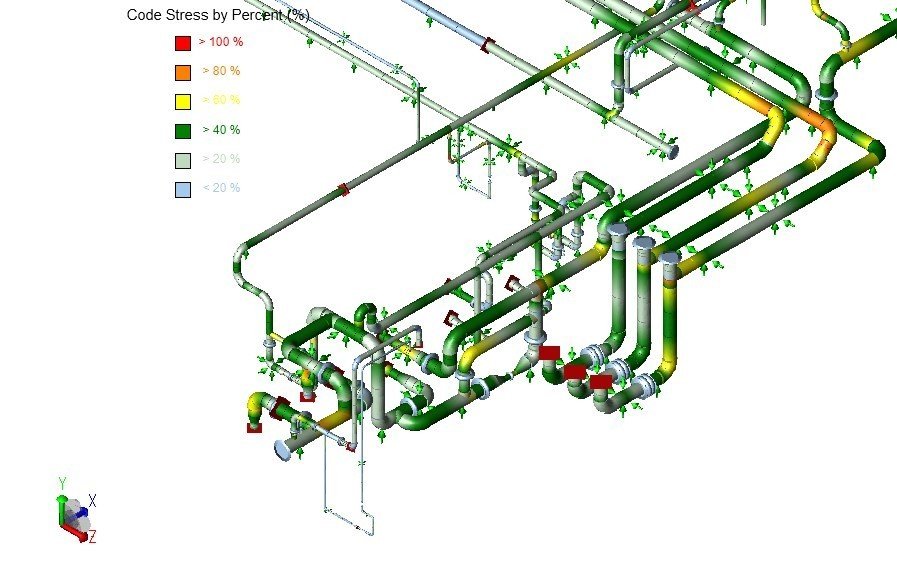

The 3D modeling for the entire pipeline network with all the bends and runs along with initial support locations are captured and modeled using pipe stress analysis software such as CAESAR-II, Bentley AutoPIPE.

The piping system are appropriately modeled accounting for their loss coefficient and elevation.

The analysis shows the displacement for the pipes at different locations and also the stresses caused due to operating & occasional loads. Various combinations of loading on the pipeline are provided as per applicable standards, which includes:

-

Dead load

-

Pressure Load

-

Thermal Load

-

Seismic loads

3. Outputs

-

The stress ratio for the different load combinations.

-

Forces & Moments acting on each support in all 3 directions.

-

Stress Isometrics for Piping network.

-

Structural steel support for Piping system to sustain various loads.

-

Design modifications like additional supports & their types, if required in piping network, to reduce the stresses.