1. Objective

The main objective is to design the tank internals in an effluent water tank so that the oil concentration in the Effluent water outlet is less than 40 ppm.

The internals are designed such that the inlet effluent water & oil mixture gets uniformly distributed across the sectional area of the tank & all the process parameters are achieved in normal operation of the tank.

The inlet distributor is designed to provide uniform distribution of the inlet effluent water and oil mixture across the crosssectional area of the tank.

The flow characteristics of gravity-based separation between oil and water are simulated using CFD. From these simulations, oil collected in both fixed oil skimmer and water outlet is quantified and an optimum design for the fixed oil skimmer is suggested.

2. Modeling & Analysis

Appropriate meshing schemes are used for the tank. The CFD analysis is divided in two stages, in the first stage the analysis of the inlet distributor is done to obtain the mass flow rate coming out from each slot in the inlet distributor. The velocities through the slots are studied to ensure uniform distribution inside the tank.

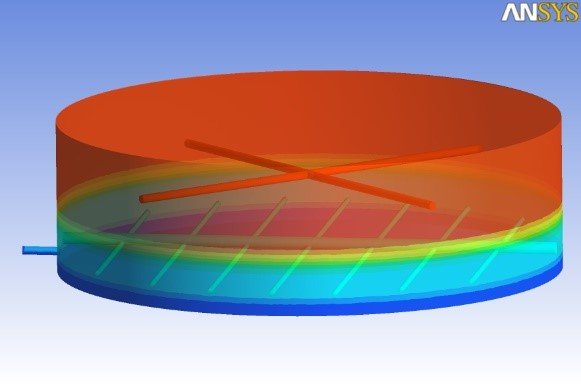

In the second stage, velocity profile obtained in the first stage are used to conduct precise flow simulation of each oil particle inside the tank. This simulation provided characteristics of buoyancy driven flow in the complete tank along with fixed oil skimmer and water outlet boundary condition.

The flow due to inlet, outlet and density difference between two fluids in the tank is then simulated to obtain the ppm of oil coming out from the outlets.

3. Outputs

-

Amount of oil going out from the water outlet.

-

Oil-Water phase separation process inside the given gravity separation tank.

-

The design of distributor slots, number of laterals and lateral length.