1. Objective

The objective of the analysis is to study pressure variation and induced stress (as per API 618 5th edition) in Inter-Stage pipe network due to pressure waves.

-

To ensure the pulsation bottles that are mounted at the inlet and outlet of / from the reciprocating compressor cylinders are even out the gas parameters (pressure and temperature).

-

To ensure stable working conditions in the compressor cylinders and eliminate / reduce vibrations.

-

To study and control of acoustic resonances in gas pipe systems caused by strong harmonic forcing from reciprocating gas compressors.

2. Design Approach

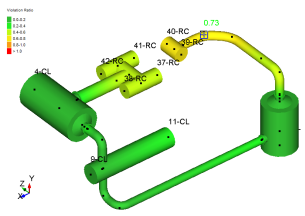

The Inter-Stage pipeline starts from suction end of the cylinder A1 & A2 and connects to discharge end of reciprocating compressors cylinder B1 and B2 via 1st Stage Discharge Snubber, Inter-Stage Cooler, Inter-Stage Accumulator, and 2nd stage Inter-Stage Snubber.

Based on the isometric drawings provided by the client, the whole piping network has been modeled. As per the process, there is one vent recovery compressor C060-5206.

Different operational cases have been done to study the effect of pressure pulsation and shake forces. Each pressure pulsation peak is compared with allowable pressure pulsation from the API-618 guidelines 5th edition.

3. Conclusion

It can be seen from the results that pulsation results are under allowable limits as pulsation waves generated by the reciprocating compressors are absorbed in pulsation dampeners and orifice plates at upstream and downstream of pulsation dampeners.

Pipelines will not face any high peak with these dampeners and orifice plates. No modification is required in the Inter-Stage piping system.

Also, it can be seen from the results obtained from dynamic stress analysis, that the pipe stresses for shake forces at different harmonics are under allowable limits.