1. Introduction to AIV Analysis Case Study

Why is a comprehensive Acoustic Induced Vibration Analysis/AIV analysis performed?

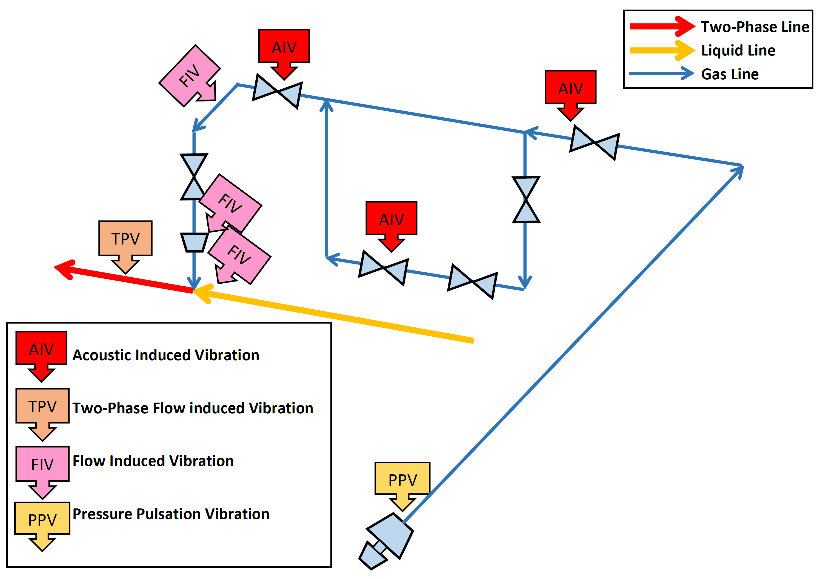

The project has Pipeline facilities comprised of various clusters, including new clusters and the addition of pipelines to existing clusters, water supply networks, disposal networks, tie-ins, and Overhead Transmission Lines (OHL) in the system. As this pipeline project involves various new and existing clusters, water networks, and other interconnected elements, there’s a potential risk of Acoustically Induced Vibration (AIV). To mitigate this risk, a comprehensive AIV analysis is being performed.

Acoustic Induced Vibration Analysis Consultants:

Acoustic induced vibration analysis consultants are professionals who specialize in assessing and mitigating the risk of vibration in industrial facilities caused by acoustic energy. These consultants have expertise in analyzing various factors, including the dynamic response of structures, acoustic power levels, fluid mechanics, and material properties, to identify potential vibration issues and develop effective solutions.

Why are AIV analysis consultants important?

AIV analysis consultants play a crucial role in the design, construction, and operation phases of industrial facilities, especially those with high acoustic energy. Their expertise helps identify potential vibration issues at an early stage, preventing costly damages, shutdowns, and safety hazards. Here are some key reasons why AIV analysis consultants are important:

Risk Mitigation

AIV analysis consultants are skilled in identifying potential risks associated with acoustically induced vibration. By conducting detailed analyses, they can assess the structural integrity of equipment, pipelines, and other components, ensuring that they can withstand the effects of vibration. This helps prevent failures and ensures a safe working environment.

Compliance with Regulatory Standards

Industrial facilities are required to adhere to various regulatory standards related to vibration and noise control. AIV analysis consultants help organizations meet these standards by providing recommendations for design modifications, materials selection, and operational practices. By staying compliant, companies can avoid penalties and maintain a positive reputation.

Cost Savings

By conducting AIV analyses, consultants can identify cost-effective solutions to mitigate vibration risks. This includes optimizing system design, selecting appropriate materials, and implementing preventive maintenance strategies. By addressing vibration issues before they escalate, companies can avoid the high costs associated with equipment failure, downtime, and repairs.

2. Objective

The objective of the Acoustic Induced Vibration (AIV analysis) / Flow Induced Vibration (FIV) Studies for the pipeline is comprised of the following:

-

The main objective of this AIV/FIV Study is to calculate the LOF (Likelihood of failure) for all new and modified piping networks.

-

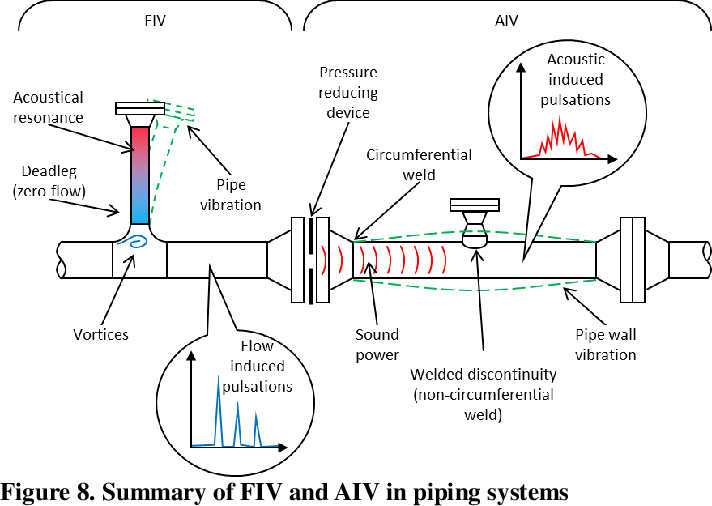

The AIV(Acoustic Induced Vibration)/FIV(Flow Induced Vibration) calculations are performed according to Energy Institute Guidelines. Vibration fatigue induced by acoustic phenomena and fluid flows is studied in all new and modified piping networks.

-

In this approach, a quantitative assessment is then undertaken to determine the likelihood of vibration-induced failures in piping systems.

-

A small bore connection assessment is performed if the LOF of the main line exceeds 0.29.

3. Critical Assumptions

-

The AIV(Acoustic Induced Vibration)/FIV(Flow Induced Vibration) study is performed based on available utility flow diagrams, process instrumentation diagrams, process data, and line schedules, as mentioned in section 3.1.

-

Process data for all streams, from utility flow diagrams, process datasheets, and line schedules, have been considered.

-

According to the Energy Institute, the valve closure time for all valves has been considered 1 second per inch of pipe diameter.

-

The pressure drops across all SDV and ROV are checked and neglected, considering lower values. Therefore, valve opening, cavitation, and flashing assessment are exempted for these valves.

-

A visual survey should be undertaken to check for poor construction and/or geometry and/or support for the main line and/or potential vibration transmission from other sources.

LOF ASSESSMENT

For the main lines, for each excitation mechanism identified as potentially at risk, a quantitative assessment is carried out to determine the likelihood of vibration-induced pipe failure. EI guidelines increase pipe wall thickness to reduce LOF.

The potential excitation mechanisms that are considered here:

-

Flow-induced turbulence

-

Acoustics Vibration assessments

-

Mechanical excitation

-

Pulsation in Reciprocating/Positive displacement pumps and compressors

-

Flow-induced excitation.

-

High-frequency acoustic excitation

-

Surge/Momentum change due to valve operation.

-

Cavitation and Flashing

4. Conclusion

Based on the detailed assessment of the pipeline and the results from AIV/FIV, the client has been given the following recommendations.

-

Acoustic-induced vibration (AIV) analysis and flow-induced vibration calculations are performed for all multiphase, liquid, and gaseous fluid systems per the Energy Institute guidelines.

-

Flow-induced turbulence for a few lines is calculated, and the value of LOF in the flow-induced turbulence study is greater than 0.5. Therefore, as per EI guidelines, a detailed analysis (Computational fluid dynamics (CFD) and structural finite element analysis) is performed.

-

High-frequency acoustic excitation: All valves’ calculated sound power level is below 155 dB. Therefore, the mainline LOF is equal to 0.29, and no further assessment of high-frequency acoustic excitation is required.