Mixing tanks are containers that mix liquids, such as paint or detergent. Computational Fluid Dynamics (CFD) is a valuable tool for predicting how long it will take for two liquids to mix and what percentage of each liquid should be combined with another.

The engineers can use this information to design the tank so that it mixes quickly and efficiently while minimizing the energy needed to power the mixing process.

What Is CFD, and How Does It Relate to Mixing Tanks?

CFD modeling is a type of computational fluid dynamics used to simulate the flow of fluids, such as liquids and gases. This simulation calculates flow properties by solving equations representing mass, momentum, and energy conservation laws.

CFD modeling can be applied to various engineering problems, such as fluid dynamics in mixing tanks. It can be used to find the optimal design for a mixing tank by calculating the forces on an impeller from the fluid flow inside.

Importance of Mixing Tanks or Tank Agitator Design

Mixing tanks are used in various industries to help mix or stir materials. Tanks are often cylindrical and powered by an electric motor or hydraulic pump. The agitator’s rotation creates a vortex that helps mix the contents inside the tank. The design of the tank and its agitator can be customized to suit specific needs.

The importance of mixing tanks lies in their ability to create vortexes when they rotate, which leads to better mixing within the tank. This is why they are often used for liquids such as paint, ink, and water-based adhesives that must be mixed well before being applied to an object.

The importance of mixing tanks in tank agitator design cannot be underestimated. The tank’s design will determine how well it blends the materials inside and how long it takes to mix them.

What Are the Advantages of CFD in Mixing Tanks?

CFD has many benefits for tank design, including predicting the pressure and velocity at any point in the tank. CFD can also optimize how fluids are mixed inside tanks, which has become more critical as chemical processes have become more complex.

It can provide insight into the tank’s performance under different conditions and make it easier for designers to optimize their designs.

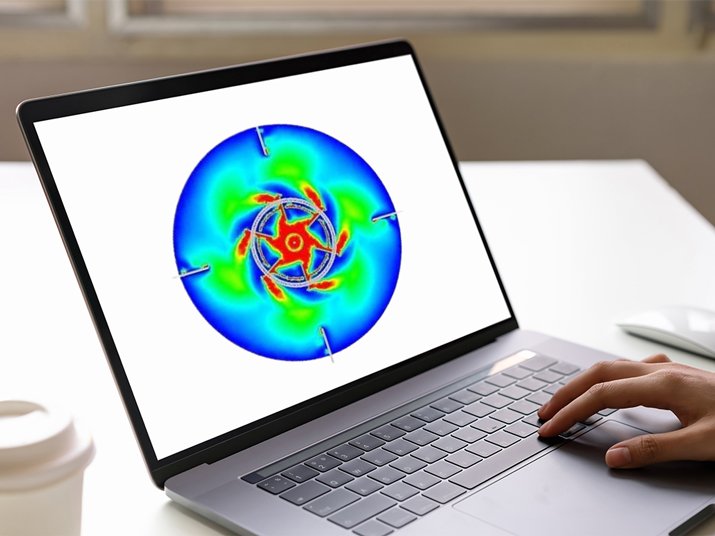

CFD simulations are run on a computer and produce a 3-D model of the fluid flow in the tank. This technique has many advantages over other methods of designing tanks, such as wind tunnel testing or using physical models.

How Does Computational Fluid Dynamics Simulate a Tank With a Mix Inside?

The simulation starts by dividing the volume into small cubes that are called cells. Then it calculates the pressure and velocity of the fluid at each cell point based on its physical properties like viscosity and density. Finally, it solves the entire flow field in the domain by using an iterative procedure called a time-marching algorithm.

This simulation will allow you to see how the fluids behave and interact.

The main idea behind CFD is that it solves the Navier-Stokes equations for the conservation of mass, momentum, and energy in a given domain. The domain can be as small as a tank or as large as an entire planet.

CFD Applications in Mixing Tanks

CFD can be applied in various industries, such as manufacturing, engineering, environmental science, and architecture. The applications of CFD in mixing tanks are mainly used for the following purposes:

1) to identify the flow patterns in the tank;

2) to optimize the design of the tank by adjusting its geometry;

3) to predict thermal stresses on tank walls.

The application of CFD in mixing tanks has enabled engineers to save time and money by reducing trial-and-error experiments. It also helps them avoid expensive redesigns due to unexpected results from physical tests.

The CFD technique has been used in the design of mixing tanks for many years. There are many benefits to using this technique, such as a better understanding of how the tank will perform under different operating conditions, reduced design time, lower costs, and improved safety.

A mixing tank is a device used to transfer a liquid from one container to another to mix the two liquids. Mixing tanks are used in many industries, including chemical processing, food production, beverage production, pharmaceutical manufacturing, and water treatment. Mixing tanks are also used for wastewater treatment, commonly known as aeration or activated sludge tanks. They work by providing an environment where bacteria can grow on organic matter (such as sewage) to break it down. Depending on the type of liquid, the tanks can be made from steel, concrete, or plastic.

The tank has an opening called a “filling port” near the bottom of the tank, where one of its two openings is either open to the atmosphere or submerged in liquid. As water is pumped into the tank, it is forced from the filling port and mixed with any liquids already in the tank. The bucket’s contents are incorporated together like a shake by passing them through a mixing paddle or agitator (a mixing blade) mounted on an axle that rotates within a central hole of the mixing blade.

Take Away

CFD is an essential tool for engineers and designers to simulate fluid flow in a given environment. Engineers can use CFD to design, analyze, and optimize a process before it is built. CFD can be used to optimize the mixing tank by considering the flow of fluids in it.

CFD simulations provide a cheaper and more efficient way to predict the flow of fluids in tanks. This is because CFD does not require any physical experimentation or expensive equipment.

As we can see, CFD is a complex topic. It has many applications and many ways to be used. You can find many resources online to learn about CFD and its workings.

Mechartes Is an Excellent Solution for Your CFD Application Needs

Mechartes has been operating for 16 years and is the leading CFD/FEA Simulations company. We’ve completed over 5,000 projects with unmatched performance and excellent customer reviews. Get in touch with us to hear more about our work.

Share

Share  facebook

facebook