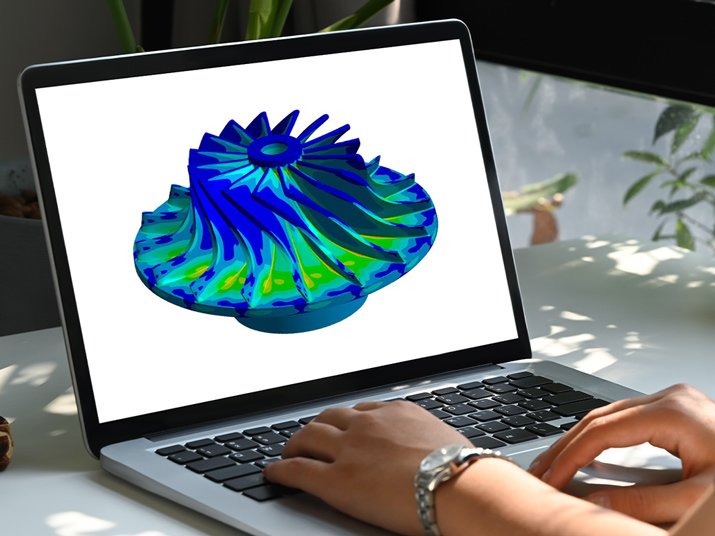

In the last five to ten years, finite element analysis (FEA) has been the preferred technique for analyzing, evaluating, and optimizing designs before physical prototyping. An FEA consultant in India offers feasible and valuable solutions to predict design vulnerabilities and prolong product life and stability.

An FEA consultant in India is now substantially more affordable for smaller engineering businesses and manufacturing companies that need advancements in computer technology.

This article overviews the various FEA solutions that can help businesses save money and time by outsourcing or hiring an FEA consultant.

5 Reasons to Outsource to an FEA Consultant in India

Using an in-house expert can be more expensive than the yearly cost of employing an FEA consultant for ad hoc, short-term initiatives.

In light of this, here are 4 reasons for outsourcing outsourcing to an FEA consultant in India.

1. Software

The acquisition and maintenance of software licenses are expensive. A single-seat license (user is granted access to protected digital software) can cost anywhere from hundreds to tens of thousands of dollars for entry-level FEA software.

Receiving upgrades and technical assistance comes at a substantial cost. The license restricts the number of program instances and even the kind and number of central processing unit (CPU) cores for a solution operation. Businesses can profit from hiring an FEA consultant with the software requirements to run FEA examinations.

2. Training

The effectiveness of FEA simulations can be greatly improved by gaining FEA experience and being familiar with the subtleties of the software packages. High-resolution models can produce more accurate findings but take considerably longer to compute.

Fast runtimes are produced by setting resolutions too low, although this can result in “garbage in, garbage out” situations. The best outcomes will be achieved by striking a balance with industry knowledge, insight, and experience.

An FEA consultant has specific skills and knowledge gained through experience to implement the right techniques and data for various FEA simulations.

3. Hardware

Businesses should use cutting-edge hardware to get the most out of an FEA license. The FEA program needed to meet specific business requirements influences some hardware decisions.

For instance, graphics cards may speed up the solving process, but not all cards are compatible.

Additionally, in circumstances where the results are extremely vast, sophisticated, or error-sensitive, professional or enterprise-grade gear may be required.

An FEA consultant may possess the right hardware compatible with the FEA program and the knowledge to run simulations based on business requirements.

Why Choose Mechartes To Meet Your FEA Requirements?

Mechartes is a renowned FEA consultant in India, offering engineering services to various industries, including automotive, manufacturing, healthcare, and aviation.

Our FEA services decrease the time from design to market, prevent unexpected field failure, lower physical testing costs, and more. We offer precisely timed technical support for each product or model to address all the difficulties in terms of static, dynamic, structural, thermal, fatigue, vibration analysis, etc.

Mechartes’ mechanical engineers, quality analyzers, and FEA specialists work as an extension of your team, using the most up-to-date technological know-how and equipment to guarantee that your designs are faultless.

Our primary solutions for finite element analysis include the following:

1. Building Analysis

When manufacturing costs, material strength, weight, etc., must be optimized, FEA structural analysis is tremendously helpful. Mechartes offers accurate FEA simulations with a structural engineering study to ensure the integrity of structures and designs.

2. Dynamic and Static Analysis

Mechartes offers static and dynamic analysis to provide accuracy and prevent machine problems. Our teams are equipped with the industry knowledge and abilities to deliver essential services within short deadlines.

3. Design Improvement

Mechartes uses the greatest and most recent FEA design optimization techniques and technologies to choose your designs’ ideal weights, materials, and dimensions.

4. Thermal Evaluation (Steady State and Transient)

Mechartes employs thermal analysis to ensure that a component or assembly’s temperature distribution is appropriate to withstand exposure to both internal and external heat sources.

5. Analysis of Stress, Fractures, and Fatigue

Using fracture growth simulation and analysis, Mechartes can forecast fatigue and how long a component will last under various complex loading conditions, such as static, dynamic, and thermal loading.

6. Various Services

In addition to the usual services stated above, we also have the necessary expertise, capacity, and skills to offer the following FEA services:

1. Pre-processing (create the model, generate an appropriate finite element grid, apply the boundary conditions, and view the complete model)

2. Post-processing (visualization of the computed results)

3. Mold flow analysis

4. Linear dynamic analysis

5. Linear and nonlinear static analysis

6. FEA modeling

Notable Case Studies By Mechartes

Mechartes has used its expertise and skills to help businesses optimize their designs. Here are two notable FEA case studies by Mechartes to enhance design integrity and performance under real-world conditions:

1. Fatigue Analysis of the Under-Vehicle Scanner

Mechartes used FEA to study the structural assembly of the pit and plate of the under-vehicle scanner.

The study aimed to test the under-vehicle scanner plate’s strength under various loading and stress scenarios. The plate was fixed to the pit with “t” and “c” supports. The structural assembly’s FEM analysis was carried out with a safety factor of 1.3 and a permitted stress 2 of 207 n/mm in mind.

Read more about this study here.

2. Fatigue Analysis of Inlet Separator

This study aimed to study the inlet separator’s fatigue life under operational settings and verify the comparable von Mises stresses under intended parameters.

3D modelling was done according to the accessible drawings. The inlet separator’s behavior under operating and design settings and the actual stress distributions in its various components were identified with FEA simulations.

The minimum requirement for vessel life is 7000 cycles for operational pressure and temperature loading to operate safely for 25 years. 12600 cycles are the bare minimum needed for a full operation span.

The calculated fatigue life was estimated to be two years at the chosen loading frequency, assuming a complete reversal in the opposite load direction.

Read more about this study here.

Get The Best Out Of FEA With Mechartes

Mechartes is an experienced FEA consultant in India who can assist you in obtaining flawless simulations every time. Clients throughout India rely on Mechartes because of its more than 15 years of experience and more than 5000 successful projects in various industries.

Click here for further details and contact information.

Share

Share  facebook

facebook