Over the last 16 years, Mechartes has dedicated its efforts to undertaking diverse and intricate construction and infrastructure projects in the Middle East and across the globe. The company’s primary objective has been to assist clients in verifying and enhancing the HVAC design for a range of projects including Data centers, Malls, Atria, Airports, mosques, temples, and churches.

This article presents an interesting analysis conducted for an airport project wherein the client employed CFD as a tool to examine the distribution of airflow and temperature within the elevator shaft, considering the influence of the elevator car’s movement.

This study helped the client’s team decide whether they need an air conditioning system or the existing natural ventilation system will be enough.

So let’s dive right in!

1.Introduction

The “Lift Shaft” used in the analysis is located inside the Passenger Terminal Building of an International Airport in the Middle East. To ensure appropriate temperatures within the lift shaft, a ventilation cutout was incorporated at the roof level, allowing for natural airflow. The study involved conducting transient CFD analysis for the lift shaft while considering the dynamic movement of the lift car.

2. Objective

The aim of this study is to investigate the temperature and airflow distribution within the lift shaft, taking into account the movement of the lift car. The analysis utilizes CFD to assess whether the existing natural ventilation system is capable of maintaining a temperature of 28±1°C inside the lift shaft during the peak summer period.

The objective is to assist the client in determining if additional measures, such as an air conditioning system, are necessary to regulate the temperature effectively.

3. Modelling

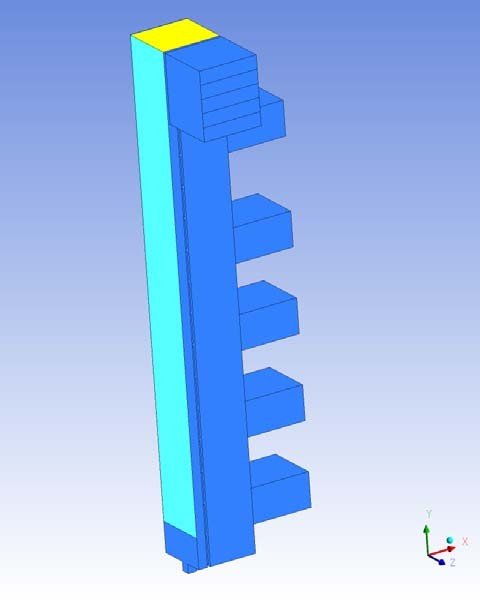

Based on the provided inputs and design drawings, a comprehensive 3D CFD model was developed using CFD software to represent the lift shaft and the lift car.

The lift shaft is naturally ventilated, featuring a ventilation opening positioned at the top. As the lift car ascends or descends within the shaft, air flows in and out through this opening. To ensure continuous airflow inside the lift car, a ventilation fan is installed, drawing air from the shaft and returning it through small gaps around the lift car doors.

To accurately simulate, appropriate boundary conditions were established. These included the lift car’s speed, the fan’s flow rate, the size of the gaps around the lift doors, and the area of the ventilation opening. Additionally, heat loads from the roof, walls, and equipment were taken into account.

Transient CFD analysis was conducted, considering both stationary and moving conditions of the lift shaft at various time intervals. The study incorporated the lift car’s movement between different floors, as well as periods of stationary positioning.

4. Recommendations

Based on the comprehensive transient CFD analysis results, it was observed that during the initial time periods when the lift car was stationary or moving between the Ground and 3rd floors, the temperatures inside the lift shaft remained below 28°C.

However, when the lift car was in motion between the 3rd and 4th floors, the temperatures inside the lift shaft at certain locations above the 3rd-floor level slightly increased to around 28.5 to 29°C, while in other areas, the temperature remained below 28°C.

As a result, we were able to inform the client that the designed natural ventilation system is capable of maintaining a temperature of 28±1°C without the need for an air conditioning system.

With Mechartés expertise in the CFD domain and the recommendations mentioned in the report the client implemented the natural ventilation system. Furthermore, using CFD Analysis early in the design process assists clients in optimizing the HVAC design by reducing the size of the mechanical system, including chillers, fans, ducts, and louvers.

We at Mechartés focus on providing accurate simulation results with a professional engineering approach. Our biggest strength is our expertise and team of young, passionate engineers who work as a close-knit unit.

Feel free to share your comments and observations at srihari@mechartes.com. You can also leave a comment or send a direct message on LinkedIn.