For the past 16 years, Mechartes have been working on various complex and unique building and infrastructure projects in the Middle East and across the globe in supporting the client to validate and optimize the HVAC design for Malls, Atria, Airports, mosques, temples, and churches.

In this article, we will see how the client used computational fluid dynamics (CFD) as a tool to optimize the HVAC design and discuss our findings and insights from CFD analysis we performed for one of the biggest mosques in the UAE.

Let’s dive right in!

1.Introduction

Indoor air quality in a mosque is influenced by the behavior of airflow, temperature distributions, and relative humidity, which vary with the number of people occupying the building.

Inside the mosque, it is imperative to maintain comfort levels during prayer when many visitors are praying and standing.

CFD Analysis helps designers and clients optimize the HVAC design inside the prayer hall to maintain proper airflow and temperature, often reducing the cooling and wastage of energy.

2. Objective

The work aims to check the parameters below for the designed air conditioning system and the given heat load conditions for the circulation areas in the mosque’s perimeter.

i. To check whether the proper air circulation is maintained or not

ii. To check whether the temperature of 23 °C is maintained.

iii. To check whether the relative humidity of close to 50 % is maintained.

3. Modelling

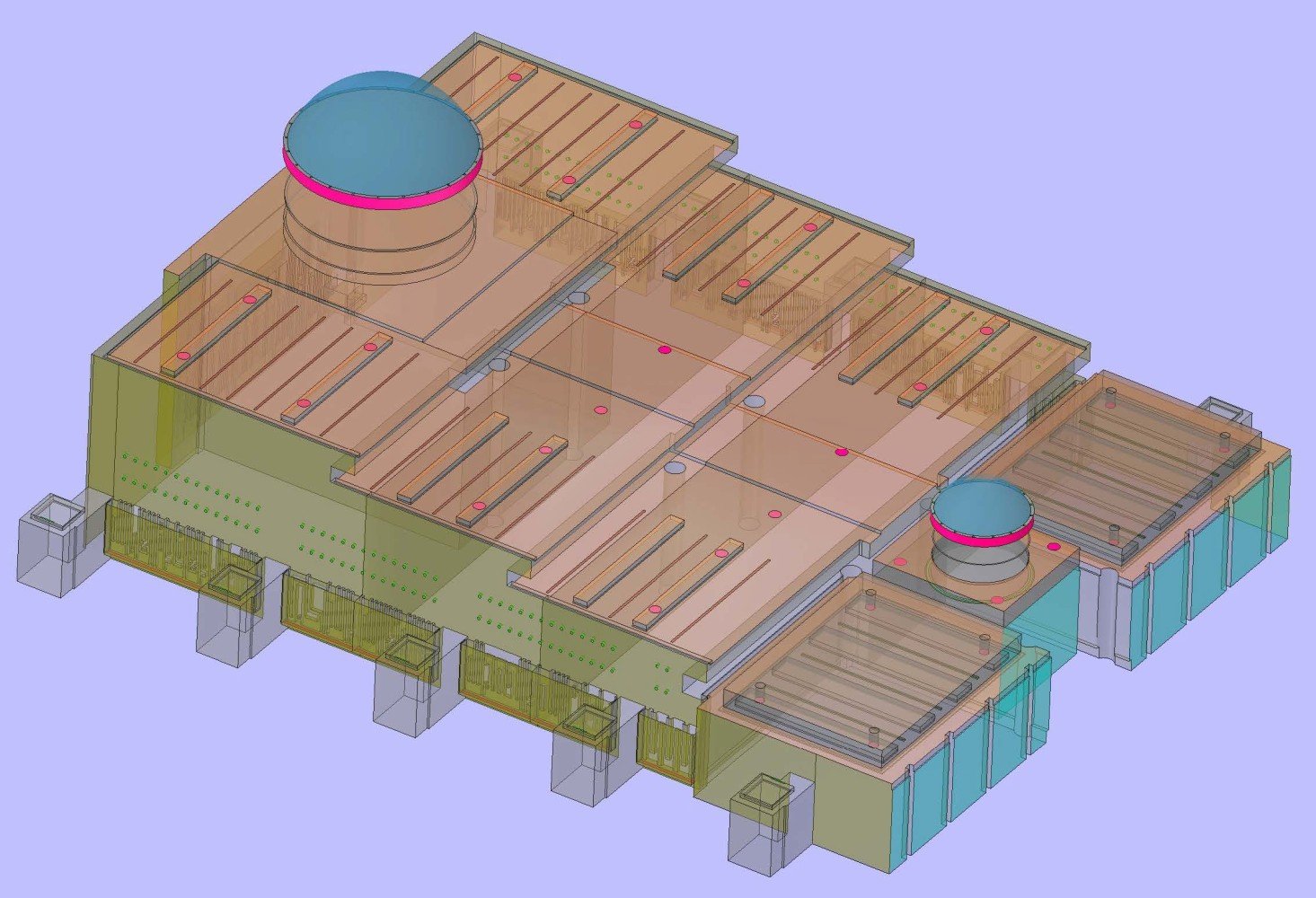

Per the inputs and design drawings received, a detailed 3D CFD model of the Mosque was created in the CFD Software.

The air conditioning system was designed to supply air from the supply air bar grille, supply linear slot diffusers, and jet nozzles at the mosque’s entrances, women’s daily prayer hall, men’s daily prayer hall, and the main prayer hall. On the other hand, the return air is extracted from the exhaust & return air grills at the women’s daily prayer hall, men’s daily prayer hall, and the central prayer hall atrium at a low level.

Appropriate boundary conditions, including the supply, return, and the heat load details, such as the people load, roof transmission at the roof, window, and skylight solar sensible loads distributed at the outer glazing, were all applied in the CFD software.

3D Model of the Mosque

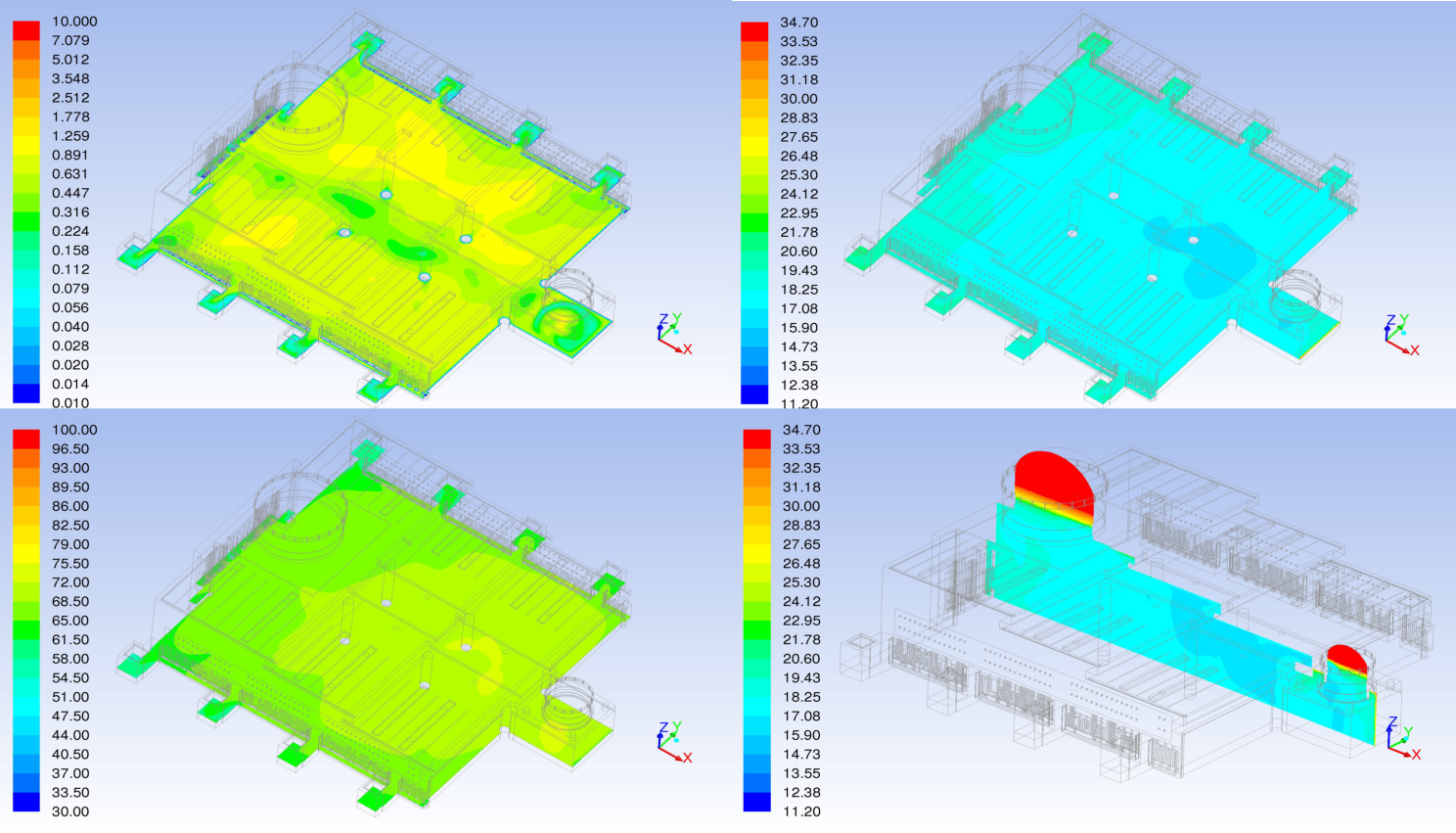

Based on the above inputs, the CFD Simulation was executed to study the velocity, temperature, and Relative Humidity profile.

4. Conclusion

Upon completion and approval of the 3D model, a steady-state CFD Simulation was performed to study the velocity, temperature, and Relative Humidity Profile inside the prayer hall.

It was observed from the study that there were no low-velocity regions; however high velocity regions in the range of 0.4 to 0.7 m/s were observed at 0.5, 1, and 1.7 meters in the Men’s, Women’s, and main prayer hall, which also resulted in overcooling of the space with a temperature range of 17 to 19 ℃ and higher Relative Humidity level in the range of 68 to 75%.

Velocity, Temperature and RH profiles

Based on the obtained results it was concluded that there was over-cooling of all the prayer halls inside the mosque during the prayer and standing position for the occupants.

5. Recommendations

Based on the detailed CFD results, Mechartes concluded that the temperature and relative humidity values at occupancy heights indicated that the prayer halls were over-cooled. It suggests that the provided air conditioning system has the excess capacity to cool the mosque during the designed heat load conditions. In order to achieve the design temperature of 23 ℃ and relative humidity close to 50%, the supply air & return airflow rates were reduced by 20 -25%, and additional CFD Analysis were carried out. It was found that the desired design conditions were met with the reduced air flow rates.

With Mechartés expertise in the CFD domain and the recommendations mentioned in the report the client avoided overcooling, which resulted in reduced operating costs and energy consumption. Furthermore, using CFD Analysis early in the design process assists clients in optimizing the HVAC design by reducing the size of the mechanical system, including chillers, fans, ducts, and louvers.

We at Mechartés focus on providing accurate simulation results with a professional engineering approach. Our biggest strength is our expertise and team of young, passionate engineers who work as a close-knit unit.

Feel free to share your comments and observations at srihari@mechartes.com. You can also leave a comment or send a direct message on LinkedIn.